Balancing Opportunity and Challenges in Chemical Recycling

The recent U.S. Plastics Pact position paper on chemical recycling has sparked a lively debate among industry experts, policymakers, and environmental advocates. This editorial aims to dig into the potential benefits and the tricky parts of chemical recycling while weighing its role within a broader circular economy system. By taking a closer look at the subject, we can better understand where this technology fits into our current environmental and economic framework.

Proponents of chemical recycling applaud its ability to break down plastics into their original molecular building blocks, thus offering a possible solution to plastic waste that is otherwise difficult to manage. Critics, however, point to the subtle details and hidden complexities of the process, such as energy consumption, emission risks, and potential health hazards. The debate is full of problems on both sides, and finding support for a balanced approach is key to moving forward.

Understanding the Tricky Parts of Chemical Recycling

Breaking Down the Technology

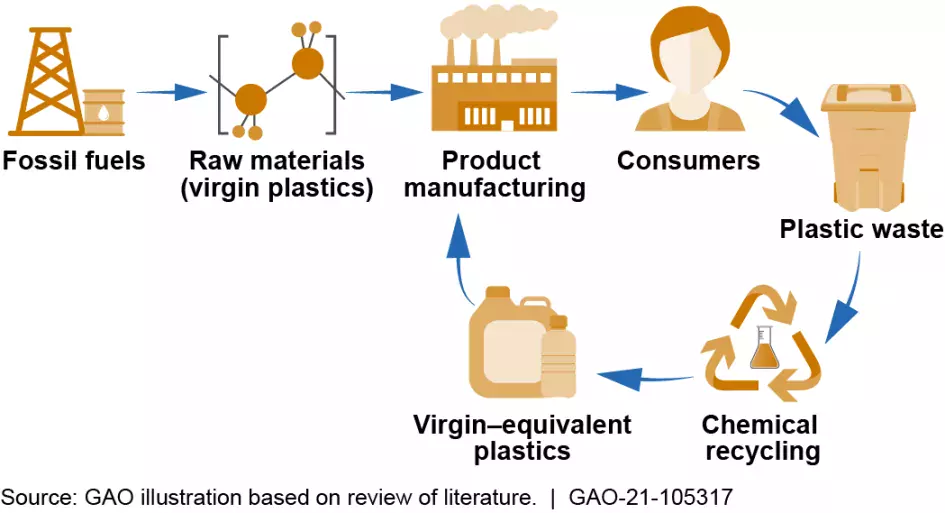

Chemical recycling, also known as advanced or molecular recycling, involves breaking down complex plastic polymers into simpler molecules that can then be reused to create new plastics. This process differs significantly from mechanical recycling, which typically involves cleaning and reshaping waste plastics. Instead, chemical recycling uses heat, chemicals, or other processes to decompose plastics into their constituent parts.

This approach offers several key advantages:

- Processing hard-to-recycle plastics: It can capture a broader range of plastics, including films, flexible plastics, and certain food-contact packaging that have been challenging to manage through mechanical recycling.

- Reducing reliance on virgin plastic: By consuming waste materials, chemical recycling could potentially lower the demand for new plastic production, thereby conserving natural resources.

- Meeting strict quality requirements: Some methods remove contaminants more effectively than traditional recycling, opening the door to using recycled content in applications with stringent standards, such as food-contact or medical-grade packaging.

However, this technology is not without its complicated pieces. Critics argue that the approach may be intimidating for communities near processing facilities and may generate environmental and health concerns if not managed with robust safety measures.

Weighing the Economic and Environmental Impact

The economic promise behind chemical recycling is significant. With industry giants and key stakeholders investing heavily in advanced recycling facilities, there is renewed hope that chemical recycling could become a major economic driver in the plastics industry. For instance, recent examples of large-scale operations, such as ExxonMobil’s advanced recycling facility in Baytown, Texas, show that these investments are starting to make a mark.

In parallel, environmental advocates see the promise of chemical recycling in reducing overall plastic waste. By breaking down materials that have long been considered unrecyclable, chemical recycling could offer a sustainable alternative that complements well-established practices like reduction, reuse, and mechanical recycling. However, the potential benefits come with caveats:

- Capital Investment Considerations: The high upfront costs and ongoing operational expenses may limit the scalability of chemical recycling technologies, especially when compared to more established recycling processes.

- Energy Consumption and Emissions: Some chemical recycling techniques require significant energy input, potentially offsetting the environmental benefits by producing considerable emissions during the process.

- Regulatory Challenges: Without clear and harmonized standards, it can be nerve-racking to determine whether these facilities truly offer a clean alternative or simply add another layer of environmental risk.

Balancing these economic and environmental factors requires careful consideration. As advocates for both economic growth and environmental protection make their voices heard, there is a pressing need for transparency and data-driven assessments to determine if chemical recycling truly lives up to its promise.

Environmental Justice and Siting Considerations

Ensuring Fair Community Impact

One of the central themes that emerges in discussions around chemical recycling is the importance of integrating environmental justice into the siting of processing facilities. US Plastics Pact stresses that chemical recyclers must consider not only the technological effectiveness of their operations but also the impact on surrounding communities. This approach is essential to ensure that the benefits of chemical recycling do not come at the expense of public health or local environmental quality.

In practice, this means that companies should:

- Assess community impact: Use tools such as California’s Enviroscreen or similar methods to gauge how potential projects might affect local communities, particularly those already shouldering a disproportionate burden of pollution.

- Implement robust safeguards: Establish standards for funding potential environmental cleanup efforts and ensure best practices for safely handling and disposing of chemicals.

- Engage in transparent dialogue: Maintain open communication with local residents and stakeholders to address their concerns and incorporate feedback into facility planning and operation.

These steps are designed to figure a path that both encourages technological innovation and respects the need for safe and equitable community development. As environmental justice continues to be a key component of federal policy—despite fluctuations in administrative priorities—ensuring that chemical recycling does not exacerbate existing problems is essential to its long-term credibility.

Comparison of Safety and Regulatory Frameworks

Safety considerations feature prominently in discussions of chemical recycling. The process itself is loaded with issues that require a robust regulatory framework. For instance, the use of high temperatures and aggressive chemicals can lead to hazardous by-products if not carefully controlled. The role of agencies such as the Environmental Protection Agency (EPA) is therefore critical in setting and enforcing standards that mitigate these risks.

The debate is further complicated by a split in perspectives at various levels of government. While some officials hail chemical recycling as an economic boon capable of reviving certain segments of the manufacturing sector, others remain wary of its potential negative externalities. This tension highlights the need for:

- Third-party evaluations: Independent lifecycle assessments (LCA) conducted by credible organizations are essential to verify that chemical recycling processes indeed offer environmental benefits compared to virgin plastic production.

- Standardized systems: Developing consistent metrics for recycling tonnages, chain of custody certifications, and mass balance calculations will help ensure that data is reliable and comparable across different facilities and regions.

- Ongoing research and monitoring: Continuous oversight and data collection will help the industry adjust practices over time, ensuring that any unintended consequences are swiftly addressed.

In many respects, the regulatory landscape for chemical recycling reflects the broader challenges of integrating emerging technologies into a complex and dynamic industrial ecosystem. Policymakers must work through these tangled issues while balancing economic interests with environmental protection.

The Role of Data Transparency and Lifecycle Assessments

Advancing Third-Party Evaluations

One of the key points raised in the US Plastics Pact position paper is the necessity for third-party lifecycle assessments. These assessments are crucial for objectively determining whether chemical recycling delivers on its promises of reduced emissions and lower environmental impact. Independent evaluations can also help to address community concerns by providing transparent, data-driven insights into how processes compare to traditional recycling methods.

In practice, improved data collection and standardized metrics should be prioritized. Industry stakeholders are encouraged to:

- Adopt transparent reporting: Publish detailed data on energy usage, emissions, and overall process efficiency to facilitate independent verification.

- Collaborate on benchmarking: Work together with regulatory agencies and independent bodies to define relevant performance benchmarks that compare chemical recycling to mechanical recycling and virgin production.

- Invest in real-world testing: Conduct pilot programs and long-term studies to understand the actual performance of chemical recycling processes and the small distinctions between different technologies.

By creating a framework for credible, third-party assessments, the industry can build trust among consumers, investors, and local communities. This level of transparency is essential for refining best practices and ensuring that chemical recycling evolves in a manner that benefits society as a whole.

Utilizing Data to Drive Sustainable Practices

Data plays a central role in helping the industry steer through the maze of competing priorities. For example, quantitative metrics can objectively assess whether chemical recycling achieves lower overall emissions than the production of virgin plastics. Detailed data not only helps in fine-tuning operational processes but also informs strategic decisions regarding facility siting and community impact assessments.

| Area of Focus | Key Metrics | Potential Benefits |

|---|---|---|

| Energy Consumption | Energy used per ton of recycled material | Optimization of resource efficiency |

| Emission Levels | CO2 and other pollutant emissions | Comparisons with virgin plastic production |

| Waste Reduction | Percentage reduction in plastic waste | Lower reliance on new plastic production |

| Process Efficiency | Recycle yield and feedstock conversion rates | Improved cost-effectiveness and scalability |

The table above summarizes key areas where data can be used to drive improvements in chemical recycling processes. Such detailed insights can illuminate the fine points of the technology’s real-world performance, thereby addressing the subtle parts that may otherwise be overlooked when evaluating environmental impacts.

Integrating Chemical Recycling with a Broader Circular Economy

Prioritizing Reduction, Reuse, and Mechanical Recycling

As the debate surrounding chemical recycling continues to evolve, it is important to recognize that no single technology is likely to serve as a silver bullet for plastic waste management. Many experts stress that chemical recycling should be a complement to more established processes such as source reduction, reuse, and mechanical recycling. This balanced approach is designed to capture those hard-to-recycle formats without displacing proven methods that already work efficiently.

In an ideal circular economy model, the hierarchy of recycling processes would look like this:

- Source Reduction and Reuse: The first step should always be to reduce the amount of plastic produced and to encourage reuse wherever possible.

- Mechanical Recycling: For plastics that can be mechanically recycled, this method should be prioritized to maintain material quality without extensive processing.

- Chemical Recycling: Used primarily for types of plastic that mechanical means cannot adequately address, chemical recycling can play a key role in capturing additional waste streams.

This tiered framework not only minimizes environmental impact but also leverages the strengths of each approach. By ensuring that chemical recycling is only used for those materials that truly necessitate a different approach, the industry can maintain a more efficient and sustainable overall recycling system.

Long-Term Vision for a Sustainable Future

The long-term viability of chemical recycling depends on continued innovation and collaboration among stakeholders. The current position paper by the US Plastics Pact is a step in the right direction, as it calls for more rigorous data collection and third-party lifecycle assessments. Future progress in this field will rely on how well the industry can manage its way through the maze of regulatory challenges and environmental concerns while embracing emerging technologies.

Key measures needed for a sustainable future include:

- Collaborative policymaking: Bringing together industry leaders, environmental advocacy groups, and regulators to establish clear guidelines and robust safety standards.

- Incremental process improvements: Continuous research and development aimed at lowering energy consumption and emissions without compromising operational efficiency.

- Community engagement: Proactive efforts to involve local communities in decision-making processes and ensure that their needs are met as new facilities come online.

- Transparent lifecycle assessments: Regular, independent evaluations that provide an honest look at the environmental benefits and potential risks of chemical recycling.

These initiatives will enable the industry to find its way through competing interests and make informed decisions based on data and community needs. As we move forward, rigorous testing and standardized reporting will be super important for ensuring that chemical recycling becomes a safe, viable adjunct to the broader recycling ecosystem.

Addressing the Scary and Overwhelming Challenges

Managing Community Concerns and Environmental Risks

Many in the community express concerns over the environmental and health risks posed by chemical recycling facilities. These worries are not unfounded, given that the process can involve high temperatures, aggressive chemicals, and energy-intensive operations. The very technologies intended to solve one problem may inadvertently introduce another if not properly regulated and managed.

To address these scary challenges, chemical recyclers should implement comprehensive risk management strategies that include:

- Stringent safety protocols: Adoption of state-of-the-art safety measures to prevent chemical spills, accidents, and harmful emissions.

- Regular environmental audits: Independent inspections to ensure that facilities continue to adhere to environmental standards and best practices.

- Community liaison programs: Establishing channels for local residents to voice concerns and receive clear, accessible information about facility operations and any potential hazards.

- Emergency response planning: Having robust plans in place to deal with unexpected incidents swiftly and efficiently.

By taking these steps proactively, chemical recycling operators can not only reduce their environmental footprint but also foster a more transparent relationship with the communities in which they operate. This approach is essential for building trust and ensuring that innovative solutions do not come at the expense of public health and safety.

Enhancing Regulatory Oversight and Industry Accountability

As chemical recycling technologies continue to evolve, it remains super important that regulatory bodies stay ahead of the curve. Recent policy debates at the federal level illustrate the need for updated standards that reflect the current capabilities and risks associated with chemical recycling. Key areas that regulators need to focus on include:

- Updating performance benchmarks: Revising emission and energy usage standards to reflect technological advancements and competitive comparisons with traditional plastic production methods.

- Mandating independent life cycle assessments: Requiring robust third-party evaluations to ensure transparency and accountability in environmental performance reporting.

- Standardizing measurement systems: Developing standardized metrics for recycling tonnages, chain of custody certifications, and mass balance calculations across all facilities using chemical recycling.

These regulatory steps will help to ensure that chemical recycling does not become a scapegoat for failing to meet broader environmental goals. Instead, it should be seen as part of a diversified strategy that includes reduction, reuse, and mechanical recycling alongside emerging technologies.

The Future of Chemical Recycling and Sustainable Manufacturing

Charting a Path Forward for Industrial Innovation

When we look at the broader industrial landscape, chemical recycling is likely to play a transformative role. The technology’s potential to improve plastic recovery, reduce reliance on new plastic production, and capture hard-to-recycle materials presents a promising vision for the future of sustainable manufacturing. However, such a future can only be realized if all stakeholders—industry leaders, regulatory agencies, and community representatives—work together to resolve the tricky parts of chemical recycling.

Key strategies for charting a successful path forward include:

- Investing in research and development: Continued investment in R&D to refine chemical recycling techniques and reduce their environmental footprint.

- Establishing clear industry standards: Collaboration among industry players to set best practices and standardized metrics that ensure transparency and safety.

- Fostering strong partnerships: Building bridges between the private sector, regulatory agencies, and local communities to ensure that economic opportunities do not trample on environmental or public health concerns.

- Maintaining a balanced perspective: Recognizing that chemical recycling, while promising, should complement rather than replace established methods like reduction, reuse, and mechanical recycling.

Looking to the future, it is clear that overcoming the overwhelming challenges of chemical recycling will require a thoughtful, data-driven approach. With consistent oversight, transparent lifecycle assessments, and a commitment to community wellbeing, chemical recycling can evolve from a controversial option into an integral part of our sustainable future.

Looking Beyond the Chemical Recycling Debate

While the focus here has been on chemical recycling, it is essential not to lose sight of the broader context of plastic waste management and sustainable practices within industrial operations. Chemical recycling is just one strategy among many that are necessary to address the ever-growing demand for sustainable solutions in waste management.

In parallel, industries are increasingly exploring innovations in alternative materials, improved packaging design, and the integration of circular economy models into everyday business operations. By approaching the problem of plastic waste from multiple angles, the entire manufacturing ecosystem can work its way through not only the technical and environmental challenges of recycling but also the nerve-racking issues related to supply chain logistics and market demand fluctuations.

This multifaceted strategy underscores the importance of collaboration across sectors. Policy decisions made by federal and state governments, investments by private companies, and grassroots coordination with local communities all play super important roles in creating a cohesive, sustainable vision for the future.

Concluding Thoughts: A Balanced Outlook for the Future

Embracing Both Innovation and Prudence

In conclusion, chemical recycling represents a promising yet challenging area of innovation in the fight against plastic waste. As the US Plastics Pact’s position paper illustrates, there are ample opportunities for reducing our reliance on virgin plastics—provided that the technology is implemented with care, transparency, and a commitment to community wellbeing.

Industry experts must remain cautious when evaluating chemical recycling, taking into consideration not only data-driven performance metrics but also the more confusing bits and small distinctions that arise from operational complexity. Whether chemical recycling ultimately becomes a staple of sustainable manufacturing will depend on how successfully stakeholders can work through its tangled issues and invest in robust regulatory oversight.

By enhancing third-party evaluations, standardizing measurement systems, and taking proactive steps to protect local communities, the industry can help ensure that chemical recycling evolves into an effective, sustainable solution. As we continue to figure a path through these tricky parts, it is clear that a balanced approach—one that embraces both technological innovation and environmental stewardship—is key to a more sustainable future.

Key Takeaways for Industry Stakeholders

To summarize this discussion, here are the super important takeaways for anyone involved in the plastics and recycling sectors:

- Technology Potential: Chemical recycling can process hard-to-recycle plastics, potentially reducing reliance on virgin materials if implemented correctly.

- Economic Considerations: High capital investment and operational costs need to be balanced against the environmental benefits offered by the technology.

- Environmental and Health Safety: Robust safety protocols and comprehensive regulatory oversight are essential to avoid introducing new risks.

- Community Impact: Incorporating environmental justice in facility siting and maintaining transparent community engagement are critical for long-term success.

- Data Transparency: Reliable, independent lifecycle assessments are necessary to verify that chemical recycling lives up to its environmental promises.

- Integrated Approach: Chemical recycling should complement established waste management strategies such as reduction, reuse, and mechanical recycling.

While it is too early to declare chemical recycling the ultimate solution for plastic waste, its role in a broader, diversified recycling strategy is clear. Industry leaders and policymakers must remain open-minded yet cautious, ensuring that decisions are informed by reliable data and real-world experiences.

The challenges are certainly intimidating, but with careful planning, clear standards, and strong community ties, chemical recycling could ultimately make a significant contribution to more sustainable manufacturing and a healthier environment for all.

As we continue to discuss the future of waste management and sustainable industry practices, it is imperative that the debate remains balanced and informed by both economic realities and environmental necessities. By taking a measured approach and fostering transparency throughout the process, the industry can help steer forward a recycling revolution that benefits businesses, communities, and the planet alike.

Originally Post From https://www.packagingdive.com/news/us-plastics-pact-position-paper-chemical-recycling/806076/

Read more about this topic at

Evaluating The Supply Chain Management Of Recycling …

Mass Balance Sparks Debate in Plastic Package Recycling