A Critical Examination of the Recent Regulatory Relief for Coke Oven Facilities

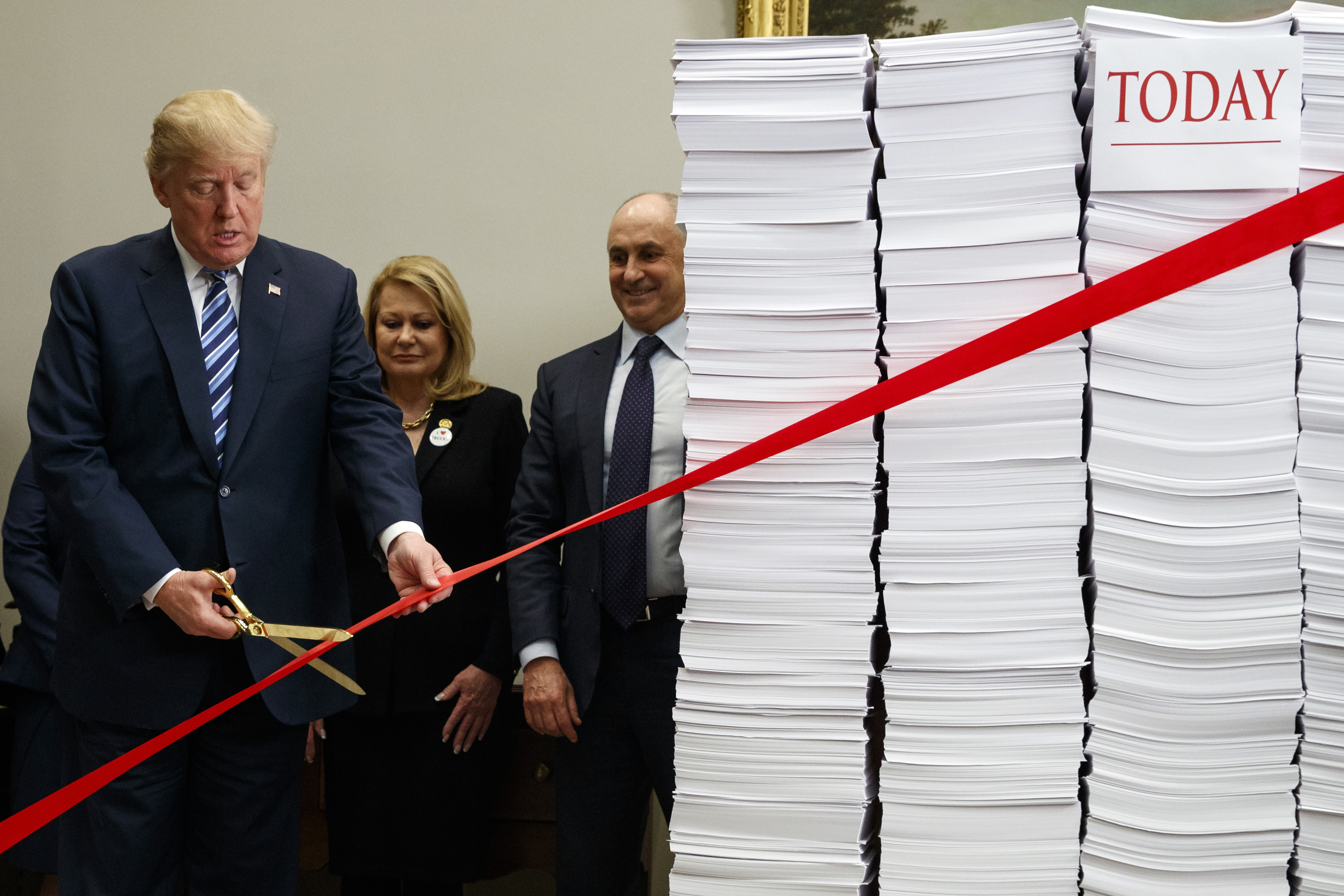

In recent weeks, we have seen a renewed focus on American industrial policy and regulatory reform amidst growing global economic pressures. The latest move granting a two-year reprieve from a stringent EPA rule on coke oven facilities is stirring debate among small business owners and heavy industry leaders alike. This decision, aimed at bolstering the domestic steel production chain, underscores the complex balance between environmental oversight and industrial growth. In this opinion piece, we take a closer look at the factors behind this measure, explore its implications for national security and economic prosperity, and discuss the challenges hidden in the twists and turns of modern regulatory policy.

At the center of this debate lies the tension between the goal of maintaining robust industrial capacity and the need to meet high environmental standards. On one side, the regulatory relief is viewed as essential in avoiding production shutdowns and debilitating costs, ensuring that critical coke production—and by extension, steel manufacturing—can continue unabated. On the other, there is concern about the long-term environmental impact of relaxing emissions standards, even temporarily. Let’s get into the fine points of how these decisions could shape the nation’s industrial landscape.

Policy Implications for American Coke Production and Steel Manufacturing

The administration’s decision to exempt certain coke oven facilities from Biden-era EPA restrictions for two years reflects a pragmatic, albeit controversial, approach to addressing tangled issues within the U.S. steel industry. Coke, produced by heating coal in the absence of oxygen, plays a critical role in the steelmaking process, with nearly 70% of all steel production relying on it to operate blast furnaces. Without sufficient access to this resource, essential infrastructure projects, defense manufacturing, and countless small businesses that depend on domestic steel could face off-putting disruptions.

Advocates of the regulatory relief maintain that forcing facilities to suddenly adapt to technologically unrealistic mandates would not only jeopardize operations but also lead to job losses and weakened national security. The administration argues that the technologies needed to meet the new standards are not yet commercially viable, making the relief not a step back for environmental protection, but rather a temporary measure to provide industry room to innovate and adapt.

Critics, however, warn that any easing of environmental oversight, even for a short period, could risk long-term ecological damage. They argue that while economic imperatives are super important, they should not come at the expense of our natural resources. Nonetheless, those in favor of the measure are quick to point out that this exemption is confined to a specific context: facilities that are essential to preserving America’s steel production capabilities, which in turn underpin national security.

Boosting National Security Through a Resilient Steel Supply Chain

A core argument behind this decision is the link between a robust domestic steel supply chain and national security. Steel is not just a commodity; it is a building block for military hardware, transportation, and critical infrastructure. When American industries and defense contractors rely heavily on foreign sources for steel and related materials, the country exposes itself to vulnerabilities from international economic and political instability.

In an era marked by global trade tensions and geopolitical rivalry, sustaining a strong domestic base for steel production is seen as a super important element of national security. With approximately 70% of steel production dependent on metallurgical coke, any disruption in this supply chain could weaken the manufacturing sector and compromise strategic defense capabilities. By granting temporary regulatory relief, the administration aims to secure this supply chain, ensuring that facilities can continue operating without the nerve-racking delays and exorbitant costs associated with meeting unrealistic new standards.

The policy shift is supported by the use of Section 232 authorities, a measure that has also been applied to impose tariffs on steel imports. This dual approach—providing domestic industry relief while countering foreign overproduction—reflects a broader strategy to bolster American competitiveness in the global market. By making your way through stringent foreign competition, American manufacturers can have a fighting chance of sustaining production and supporting jobs across diverse regions.

Balancing Environmental Priorities with Industrial Growth

One of the trickiest parts of policy-making today is finding common ground between environmental sustainability and industrial progress. The current regulatory relief is part of a broader ideological stance that prioritizes economic growth and national security, juxtaposed against environmental protection measures that some view as overly ambitious or impractical for certain high-stakes industries.

From an environmental viewpoint, critics argue that even temporary relaxations in emissions standards may encourage pollution that could have a lasting negative impact on air quality and public health. Concerns remain that such measures could set a precedent for future regulatory rollbacks. However, proponents assert that environmental protection and industrial strength are not mutually exclusive. The goal is to strike a balance where environmental rules are realistic and achievable, ensuring that industries can adjust without incurring debilitating costs or risking major disruptions.

Historically, similar approaches have been taken to reconcile these conflicting objectives. For instance, past administrations have periodically fine-tuned regulations to safeguard both the environment and the economy. The Obama-era Clean Power Plan, later replaced by a more achievable alternative during the previous administration, is a case in point. By stepping in to offer regulatory relief where expectations were too high, policymakers aimed to create an environment where both industry and the environment could thrive.

Understanding the Hidden Complexities of Technological Adaptation

Another key issue in this regulatory maneuver is the reality that the technologies required to meet the new standards remain at an early stage of development. Industries reliant on coke ovens are being asked to shoulder a heavy burden: to engineer and deploy systems that currently do not exist in a commercially viable form. This expectation is seen by many as not only intimidating but also potentially disruptive. The timeline for meeting these standards is perceived as off-putting for facilities that already operate on thin margins.

In this context, the regulatory relief should be seen as an opportunity for industry to innovate and bridge the gap between current technological capabilities and future expectations. By giving facilities time to research and develop cost-effective emissions control mechanisms, the government hopes to avoid a scenario where companies are forced to implement expensive and impractical systems under tight deadlines.

This period of leniency can serve as a window for researchers, engineers, and industry leaders to collaborate on solutions that are both economically viable and environmentally sensitive. Industry experts are calling for increased investment in research and development, as well as public-private partnerships to tackle these challenges head-on. Such efforts will be essential in creating technologies that address the small distinctions between current capacities and the lofty requirements set by new standards.

Industrial Innovation in the Face of Regulatory Challenges

In analyzing the current situation, it is important to recognize that the relief measures are part of a larger strategy to promote industrial innovation. Throughout the history of American manufacturing, moments of regulatory easing have often led to a surge in inventive solutions. By alleviating some of the confusing bits of bureaucratic pressure, the government aims to foster an environment where industries can focus on innovation rather than on meeting impractical mandates.

The strategy involves encouraging industries to develop emissions control technologies that are not only effective but also financially sustainable. This approach emphasizes the need for targeted investments in industrial research and the creation of incentive programs that reward companies for early adoption of new technologies. Key sectors, such as semiconductor manufacturing, chemical production, and specialized materials processing, have already seen the benefits of such initiatives.

A balanced regulatory environment can help ensure that American industries remain competitive in both domestic and international markets. By tackling the nitty-gritty of regulatory expectations, manufacturers are better positioned to invest in next-generation technologies and drive economic growth. At the same time, it remains essential for policymakers to maintain stringent yet achievable environmental goals to safeguard public health and the natural environment.

Economic Benefits and Concerns for Small Businesses

Small businesses are among the most affected by shifts in industrial policy, as they often have fewer resources to manage sudden changes in regulations and compliance standards. The recent regulatory relief is seen as a welcome measure by many small business owners who fear that the stringent compliance requirements would have forced closures and job losses.

For small businesses connected to the steel production chain, particularly in regions where manufacturing forms the backbone of the local economy, the relief can provide much-needed breathing room. It enables them to continue operations and maintain employment levels while giving them time to develop and integrate improved emissions technologies.

Despite these benefits, concerns persist that the temporary nature of the relief may not lead to long-term stability. There is a risk that once the two-year period expires, businesses will again face off-putting regulatory demands without sufficient technological support. This underscores the need for a forward-looking strategy that includes not only temporary relief but also a phased, supportive transition toward cleaner, more efficient production practices.

Key points for small businesses include:

- Maintaining operational continuity and avoiding sudden shutdowns

- Investing in innovation and compliance technologies during the relief period

- Leveraging government incentives and public-private partnerships for modernization

- Engaging in dialogue with policymakers to ensure balanced, achievable regulations

These factors highlight the need for collaborative efforts between industry leaders, small business advocates, and regulatory bodies. Only through such cooperation can we ensure that environmental goals are met without sacrificing the economic lifeblood that supports communities across the nation.

Technology, Research, and Public-Private Collaboration

The regulatory relief period has been presented as a chance to develop and deploy newer, more efficient technologies. This process requires a collaborative approach where innovation is at the forefront of policy implementation. Researchers in environmental science, engineering, and industrial manufacturing are joining forces with private enterprises to figure a path toward sustainable yet pragmatic solutions.

A combined effort in targeted research and development could yield technologies that are both cost-effective and environmentally sound. Some potential focus areas include:

- Advanced emissions control systems for coke ovens

- Innovative catalysts and combustion techniques to improve efficiency

- Data-driven monitoring systems to ensure compliance while minimizing costs

- Collaborative pilot projects between government agencies and private companies

By incentivizing these areas of research, the administration can facilitate a smoother transition once the relief period ends. This approach mitigates the risk of reversals in policy that might otherwise stifle innovation. It also underscores that while short-term regulatory easing provides immediate benefits, long-term investments in technology are essential for sustained progress.

Assessing the Broader Impact on Economic Resilience

The decision to grant regulatory relief to coke oven and steel industries is not made in isolation. It is part of a broader strategy to build economic resilience in the face of international competition and ongoing supply chain challenges. The core idea is that a strong domestic industrial base can better withstand external pressures, ranging from trade disputes to sudden geopolitical shifts.

Economic resilience is built on several pillars, including domestic production capability, technological innovation, and regulatory frameworks that support rather than impede progress. In this framework:

- Strong domestic production ensures that critical industries, such as steel manufacturing, remain competitive.

- Investment in technology helps address the small distinctions between current operational capabilities and future regulatory requirements.

- Balanced policies provide the necessary breathing room for industries to adapt while safeguarding national interests.

What is clear from this interplay is that protecting domestic interests goes beyond short-term policy adjustments. It requires a concerted effort to design regulations that acknowledge the realistic challenges faced by industry while still safeguarding public welfare and environmental quality.

Weighing the Short-Term Benefits Against Long-Term Goals

A critical part of this conversation revolves around whether the short-term benefits of regulatory relief can be aligned with long-term economic and environmental objectives. While immediate alleviation of regulatory pressure is welcomed by many in heavy industry, there are valid concerns regarding the potential delays in environmental advancements.

Short-term benefits include:

- Sustained operation of key coke and steel production facilities

- Prevention of job losses in regions dependent on heavy manufacturing

- Enhanced national security through a robust domestic industrial base

- Opportunities for research and development to innovate cleaner technologies

Long-term goals, however, must balance these immediate advantages with a commitment to reducing pollution and improving public health. Policymakers need to ensure that the temporary relief does not set a precedent for indefinitely postponed environmental progress. The hope is that the period of regulatory easing will serve as a springboard for innovation, rather than a backdoor to permanent deregulation.

To manage this transition effectively, policymakers are encouraged to:

- Set clear, time-bound targets for technological upgrades and environmental improvements

- Increase funding for research into sustainable industrial practices

- Engage with industry representatives to create adaptive, realistic timelines for compliance

- Monitor environmental impacts closely to ensure that any relaxation in standards does not lead to significant degradation

Guiding these efforts will be essential in ensuring that the benefits of regulatory relief are not outweighed by long-term risks. Achieving a balance that addresses both economic and environmental concerns will require ongoing dialogue and collaboration between government, industry, and environmental groups.

Energy Dominance and the Role of Domestic Production

Another aspect worthy of discussion is how energy policy intermingles with industrial manufacturing. The administration’s track record on promoting domestic oil and gas production is well known. It is part of a broader energy dominance strategy aimed at reducing reliance on foreign energy sources while ensuring that environmental oversight remains practical. The regulatory relief for coke and steel production is in line with these broader efforts.

Domestic energy and manufacturing policies have historically been intertwined. When energy production is robust, it provides a foundation upon which industrial sectors can build. Conversely, a strong industrial sector ensures that the energy produced domestically is used effectively to power economic growth and maintain critical infrastructure.

This policy move underscores a pragmatic view: energy development and industrial innovation are not mutually exclusive. Instead, they can be mutually reinforcing if managed judiciously. Investments that help domestic producers modernize their facilities not only protect key jobs but also secure a more reliable supply chain for energy-intensive industries.

Ultimately, the long-term vision is to achieve a state where economic growth, industrial innovation, and environmental sustainability coexist. This will require continuous adjustments to regulatory frameworks based on evolving technological capabilities and market dynamics.

International Trade, Tariffs, and Domestic Industry Protection

The broader backdrop to this decision also involves international trade policies and the use of tariffs to protect domestic industries. The application of Section 232 authorities—in which a 50% tariff was imposed on steel imports—served as an additional layer of protection for American manufacturers. This move was designed to counter the effects of foreign overproduction, which could undermine the domestic market.

Critics of such measures argue that tariffs can lead to retaliatory actions and increased costs for American consumers. However, proponents insist that in sectors where national security is intertwined with industrial capacity—like steel manufacturing—such measures are essential. The goal is not merely to shield domestic companies but to ensure that critical industries can keep contributing to national defense without interference from foreign market forces.

For those keeping a close eye on international trade, this regulatory relief is a sign that domestic industries are being given room to maneuver intelligently amidst global uncertainties. It is a reminder that in times of international tension, having a secure, self-sufficient industrial base is not just an economic advantage—it’s a national imperative.

Small Business Perspectives on Regulatory Adjustments

Small businesses frequently operate at the crossroads of regulatory changes and are among the most vulnerable when it comes to adapting to new policy frameworks. For many small to mid-sized manufacturers tied into the coke and steel production chain, the new regulatory relief provides a crucial window of opportunity. This is time to catch up with emerging technologies and restructure operations to prepare for future compliance demands.

Business owners in this sector often face overwhelming regulatory requirements that could force them to reconsider long-established processes. The nerve-racking prospect of overhauling entire production systems on unrealistic timelines has been a persistent worry. With the temporary relief period in place, these companies can divert more resources into research, innovation, and training rather than incurring heavy costs for immediate compliance.

Key concerns for small businesses include:

- Availability of funding and government support for technological upgrades

- Sufficient time and clear guidelines for transitioning back to stricter standards

- Long-term strategies for staying competitive without compromising on environmental goals

- Protection against potential future regulatory shocks

By focusing on these core issues, small business owners can take proactive steps to secure their operations. The opportunity to innovate during this period may lead to the development of cost-effective and environmentally friendly technologies, thus ensuring their continued contribution to both local economies and the nation’s industrial backbone.

Government and Industry: Finding Common Ground

One of the challenges faced by policymakers is managing the many tricky parts of balancing the interests of industry and the requirements of rigorous environmental policy. Through this regulatory relief, there is a signal that the administration is open to tailored approaches that acknowledge the real-world constraints of industrial operations. Instead of enforcing a one-size-fits-all mandate, the approach here is to allow industry leaders to catch up technologically, with the expectation that new solutions will emerge during this grace period.

Several measures could be considered to synergize these goals:

- Regularly scheduled reviews of technological progress and environmental impact during the two-year period

- Enhanced communication channels between industry representatives, environmental experts, and policymakers

- Joint task forces to address the little twists and turns emerging from compliance challenges

- Clear benchmarks and performance indicators to evaluate the success of regulatory easing

By fostering a collaborative environment, both industry and government can work together to steer through the confusing bits of these regulatory challenges. This cooperative approach not only facilitates innovation but also builds a foundation of trust and mutual understanding that will be key for any future policy adjustments.

Long-Term Outlook: Transitioning to Sustainable Industrial Practices

While the current regulatory relief is framed as a temporary measure, it prompts us to consider the long-term trajectory for American manufacturing. The ultimate goal is to evolve toward production methods that are both eco-friendly and economically viable. Instead of permanently watering down standards, the relief period is an interim phase intended to catalyze innovation.

Looking ahead, several strategies could help chart a course for sustainable industrial practices:

- Developing a clear roadmap for gradual roadmap adjustments that integrate stricter environmental standards over time

- Investing in advanced research initiatives that bridge today’s production capabilities with tomorrow’s technological possibilities

- Encouraging pilot programs that test and validate new emissions control technologies under real-world conditions

- Creating incentives for companies that achieve early compliance and demonstrate measurable improvements in sustainability

If successful, such strategies will not only mitigate short-term economic disruptions but also set the stage for a new era of sustainable industry. The vision is to have an American manufacturing landscape where environmental performance and industrial productivity support each other, turning what might seem like disconnected regulatory mandates into a cohesive path forward.

The balancing act will remain delicate, and the need to adapt to evolving technological, economic, and environmental realities will always demand flexibility and foresight. However, by embracing the opportunity provided by the current regulatory relief, American industries can use this period as a proving ground for the innovations that will define the future.

Conclusion: Charting a Course Through Confusing Bits and Tangled Issues

In conclusion, the decision to grant regulatory relief for coke oven facilities is a multifaceted policy move that highlights the challenge of managing the variable twists and turns of modern industrial regulations. The temporary easing of compliance demands is designed to protect critical elements of America’s steel production chain—a chain that is closely tied to national security and economic resilience.

While the relief has been met with both support and skepticism, its long-term effectiveness will depend on how well industry, government, and other stakeholders can use this time to innovate and prepare for a future where stricter environmental standards are once again enforced. This period is a call for collaboration, research, and the application of pragmatic solutions that align economic interests with sustainable practices.

Ultimately, the key takeaway is that industrial policy should not be seen as a static set of mandates but as a dynamic framework that evolves with technological advancements and market realities. Policymakers need to remain responsive to the fine shades of industry challenges—whether it’s the daunting task of retrofitting outdated systems or the need to find your way through the small distinctions between temporary relief and permanent reform.

For those invested in the future of American manufacturing—be it small business owners on the frontlines or large industrial conglomerates—the current measures offer both an opportunity and a challenge. The opportunity to innovate, retool, and demonstrate that domestic production can meet global demands without sacrificing either national security or environmental integrity. The challenge lies in converting this window of regulatory leniency into lasting progress that benefits all stakeholders.

As we watch the developments in this arena, it is worth reflecting on a central truth: progress often involves taking calculated risks, finding your way through tangled issues, and leveraging temporary setbacks into stepping stones for future success. With robust dialogue, collaborative research, and a willingness to adapt, American industry can emerge stronger and more resilient, setting an example for regulatory frameworks worldwide.

The future of industrial policy in America will undoubtedly require more than quick fixes and temporary relief. It will necessitate a commitment to continuous learning, adaptation, and innovation—qualities that have long defined the nation’s entrepreneurial spirit. As businesses and governments navigate the inevitable complexities of modern regulation, the lessons learned during this period could pave the way for a more balanced and sustainable industrial ecosystem.

In the end, whether one views the current regulatory relief as a pragmatic solution to a series of intimidating challenges or as a risky postponement of necessary environmental reforms, it is clear that the stakes are high. The outcome of this policy experiment will likely influence not only the future of coke production and steel manufacturing but also the broader interplay between industry, environment, and national security in the years to come.

By ensuring that the discussion remains focused on innovation, collaboration, and sustainable progress, we can hope to turn these temporary measures into catalysts for a truly resilient and forward-thinking industrial future.

As industry leaders continue to take the wheel in finding practical solutions to these complicated pieces of modern regulation, it is incumbent on policymakers to provide the guidance and support necessary to make this transition as smooth as possible. The coming months and years will reveal whether this regulatory relief can serve as a blueprint for balancing critical economic needs with environmental stewardship—a delicate, yet super important, endeavor for America in the global arena.

Only time will tell if this approach will truly enable American industries to thrive amid global competition and domestic challenges. However, what is indisputable is the need for smart, well-coordinated strategies that consider the full spectrum of this issue—from the nitty-gritty of technological adaptation to the broader goals of national security and sustained economic growth.

Read more about this topic at

Regulatory Relief for Certain Stationary Sources to …

How Steel Tariffs Protect American Jobs: Todd Leebow on …