Direct Lithium Extraction: A Game-Changer in Energy Resources

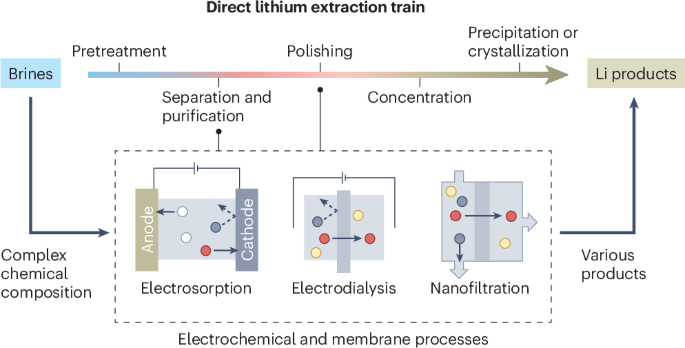

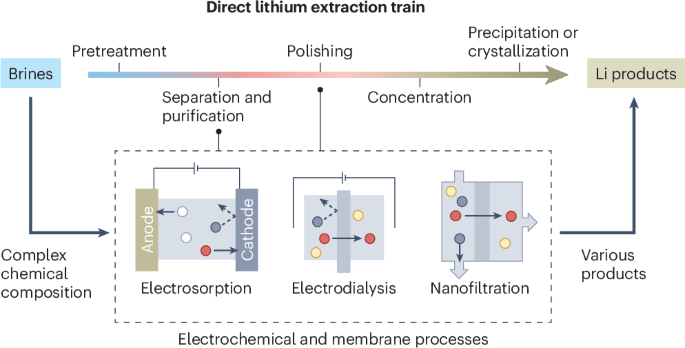

The rising demand for batteries in electric vehicles and renewable energy storage has spurred intense debate about the best routes to sourcing lithium. Traditional methods like pond evaporation and chemical precipitation have long been the mainstay, but new approaches involving membrane and electrochemical separations are catching the eye of experts. In this editorial, we take a closer look into these emerging technologies, discussing their potential, the tricky parts involved, and how they might reshape the industry.

Understanding Brine Chemistry and Its Impact

The foundation of any successful lithium extraction process lies in the characteristics of the brine sources. Whether coming from salt lakes, geothermal deposits, or oilfield-produced water, each source presents its own set of tangled issues that must be addressed. The chemical makeup of these brines—rich in magnesium, boron, and other competing ions—means that the separation process must be both selective and robust.

Key considerations with brine chemistry include:

- Balancing the ratios of lithium to other ions

- Managing the presence of interfering species that complicate the separation process

- Understanding seasonal and regional variations in brine composition

When investing in advanced extraction technologies, companies have to figure a path through these confusing bits. Dealing with high magnesium-to-lithium ratios, for instance, calls for a selective method that can efficiently target lithium even when other ions flood the system.

Membrane Technologies: Digging Into the Details

Membrane processes, particularly nanofiltration, are gaining popularity as a method to directly extract lithium from complex brines. These membranes operate by allowing some ions to pass through while blocking others based on size, charge, and interactions with the membrane material.

Some of the fine points of these membrane systems include:

- Ion selectivity: The ability of a membrane to favor lithium over magnesium or other contaminants is super important. Fine-tuning the membrane structure can lead to more effective separation.

- Material sustainability: Membranes must be stable, durable, and able to work under tough conditions. Selecting the right materials is a critical step that involves navigating through a range of material properties and long-term performance issues.

- Operating conditions: Pressure, temperature, and flow rates all influence the performance of a nanofiltration system. Operators need to work through the subtle parts of tweaking these parameters to reach optimum performance.

A comparative table below illustrates some of the differences between various membrane-based techniques for lithium extraction:

| Parameter | Nanofiltration | Reverse Osmosis | Electrodialysis |

|---|---|---|---|

| Selectivity | High for small ions | Varies with membrane type | Dependent on applied voltage |

| Energy Consumption | Moderate | High | Potentially low with optimized setup |

| Operational Complexity | Some tricky parts, but manageable | Loaded with issues due to fouling and scaling | Can be intimidating at first |

The table shows that while nanofiltration has its own nuances, it often balances energy needs and selectivity better than some of the alternatives. However, all these methods involve a set of complicated pieces that require careful calibration.

Electrochemical Separations: A Closer Look at the Process

Electrochemical approaches, from electrodialysis to electrosorption, are also rising stars in the arena of direct lithium extraction. These methods use electrical potential to induce ion movement, with the promise of continuous extraction and lower energy demands under certain conditions.

When we take a closer look into the mechanics of these processes, we find several key aspects that define their performance:

- Electrochemical gradients: By applying a voltage across membranes or electrodes, specific ions such as lithium are encouraged to move in a controlled manner. This technique helps in sidestepping some of the nerve-racking issues associated with traditional chemical methods.

- Material considerations: The choice of electrode material is full of problems that require attention. Stability, resistance to scaling, and the risk of dissolution in harsh brine environments are all factors that engineers must manage their way through.

- Process integration: Integrating these electrochemical techniques into existing lithium recovery systems can be a daunting task. Operators might need to figure a path around the small distinctions in system design to achieve seamless performance.

Electrodialysis, in particular, offers a platform where membranes and electrode configurations work together. By using ion-specific membranes, the process can potentially achieve near-perfect selectivity in separating lithium from its competing ions.

Here is a simplified schematic in bullet-list form that summarizes the steps involved in an electrodialysis-based lithium extraction process:

- Pre-treatment of brine to remove large particles and precipitates

- Application of an electrical field to drive the separation of ions

- Selective transfer of lithium ions through specially designed membranes

- Collection of the lithium-enriched stream for further refinement

- Recycling of the remaining brine after extraction

Overall, electrochemical methods might seem intimidating due to their technical setup, but with proper design and material selection, they have the potential to significantly reduce the energy input and improve the product purity.

The Role of Operating Conditions and Materials in System Efficiency

Both membrane and electrochemical methods face challenges that stem from the operating conditions and the materials used. In addition to the inherent fine points of ion separation, there are several external factors that require careful management:

- Temperature variations: Fluctuating temperatures can lead to changes in ion mobility and membrane stability. The effect of heat can be both beneficial and detrimental, depending on the system design.

- Pressure and flow rates: The pressure applied in membrane systems affects the rate at which ions pass through. Similarly, in electrochemical systems, flow rates of the brine influence the overall performance.

- Chemical compatibility: The long-term exposure of membranes or electrodes to a harsh chemical environment can lead to degradation. Understanding these hidden complexities is a must-have for designing robust processes.

To illustrate the interplay between operating conditions and performance, consider the following bullet-list of recommendations:

- Regular monitoring of brine composition to adjust process parameters

- Incremental testing of membrane durability under varying pH and salinity

- Periodic electrode cleaning or replacement to counter scaling and passivation

- Utilizing adaptive control systems to adjust voltage, pressure, and flow in real time

This integrated approach helps mitigate the overwhelming challenges that come with raw material variability, ensuring the process remains efficient and reliable.

Economic Considerations and Market Dynamics

While the technical aspects are fascinating, the economic reality behind lithium extraction cannot be ignored. With global markets constantly shifting and governments worldwide emphasizing renewable energy, the economic stakes are high. Companies must weigh the benefits of advanced membrane and electrochemical techniques against the traditional, tried-and-true methods.

Some of the key economic factors include:

- Capital Investment: Advanced extraction technologies require significant upfront investment. The cost of developing specialized membranes or electrochemical cells can be off-putting at first, but the long-term gains might justify the price.

- Operational Costs: Energy consumption and maintenance costs add up quickly. The efficiency of membrane separations in reducing energy input can present a compelling case, especially when integrated with renewable energy sources.

- Market Pricing: Lithium prices are subject to global supply and demand dynamics. As the EV market grows and renewable energy storage becomes more common, securing a reliable and cost-effective source of lithium becomes a super important strategy.

A summary table below outlines some of these economic considerations:

| Economic Factor | Traditional Methods | Membrane/Electrochemical Methods |

|---|---|---|

| Capital Investment | Lower initial cost | Higher, due to advanced equipment |

| Energy Consumption | High (inefficient evaporation and precipitation) | Potentially lower with optimized systems |

| Operational Complexity | Relatively simple but environmentally taxing | Loaded with technical issues but more environmentally friendly in the long run |

| Environmental Impact | Potentially high, due to large evaporation ponds and chemical usage | More controlled and easier to mitigate adverse effects |

Investors and industry leaders must dig into these economic details to build a sustainable business model that marries technological innovation with financial viability.

Environmental Impacts and Sustainability Challenges

The environmental implications of lithium extraction have become a hot-button issue recently. More refined processes not only aim to maximize output and efficiency but also strive to minimize environmental damage. Traditional evaporation ponds, for instance, can significantly disturb local ecosystems and consume vast amounts of water. In contrast, advanced techniques such as membrane filtration and electrochemical separations offer promising routes to more sustainable extraction.

Key environmental advantages include:

- Reduced water usage: Membrane methods can be designed to recycle a large portion of the input brine, reducing the overall water footprint.

- Lower chemical waste: By avoiding heavy chemical precipitation and reducing the need for reagents, modern techniques cut down on hazardous waste generation.

- Energy integration: Many emerging processes can be powered by renewable energy sources, which helps mitigate the overall carbon footprint associated with extraction.

However, it is not all smooth sailing. Some of the challenging parts that environmental engineers face include:

- Ensuring that the advanced materials used in membranes or electrodes do not themselves lead to pollution when they are disposed of

- Managing the lifecycle impacts of these technologies so that the environmental savings in operation are not offset by production or disposal issues

- Balancing local ecological considerations with the global demand for lithium

Taking a closer look into the sustainability of these technologies, decision-makers must figure a path that weighs process efficiency against the potential ecological footprint.

Scaling Up: Moving from Laboratory to Large-Scale Production

One of the greatest challenges for innovative extraction technologies is scaling up from pilot studies to full-scale industrial operations. The success of a laboratory prototype does not always translate seamlessly into a commercial plant. Many companies have reported that the transition process is full of tricky parts and surprising twists and turns. Engineering teams need to consider:

- System robustness: Large-scale operations demand steady performance even when faced with significant fluctuations in brine composition and operating conditions.

- Integration with existing infrastructure: Enabling advanced extraction methods to dovetail with current production lines is a complicated piece of the puzzle. This often involves retrofitting older systems with modern technologies.

- Continuous operation: Processes such as electrodialysis or nanofiltration must be designed for continuous performance over long durations. This requires careful management of fouling, degradation, and maintenance schedules.

To successfully scale up, companies can benefit from taking small, iterative steps. A phased approach might look like this:

- Initial pilot implementation in controlled environments

- Gradual adaptation to real-world conditions with monitored performance metrics

- Incremental capacity expansion while refining operational protocols

- Full-scale deployment integrated with supply chain and renewable energy sources

The evolution of direct lithium extraction into a mature technology relies heavily on how well engineers and decision-makers can figure a path through these tricky scale-up issues.

Future Prospects and Industry Implications

As the world’s reliance on lithium continues to grow, the pressure to adopt cleaner, more efficient extraction methods will only increase. Membrane technologies and electrochemical separations are poised to become key players, particularly in an industry that is constantly on edge with new environmental regulations and market shifts.

Looking ahead, there are a few interesting trends that suggest a promising future:

- Integration with renewable energy: The use of solar-driven membrane separation or energy-efficient electrochemical cells is expected to become more common as green energy becomes more accessible.

- Advanced process control: With artificial intelligence and machine learning increasingly used to steer through operational challenges, processes can be continually optimized in real time.

- Material innovation: Ongoing research is likely to bring forth new materials that better tackle the hidden complexities of ion separation, thus enhancing efficiency and durability.

The implications for industries such as automotive and energy storage are significant. As the extraction process becomes more compact and sustainable, market competition is likely to grow, leading to a healthier supply chain for a lithium-driven future.

Challenges and Opportunities: Finding Your Path in a Competitive Landscape

Even with promising technological advances, the path to widespread adoption of membrane and electrochemical methods is loaded with potential pitfalls. There remain several nerve-racking issues that stakeholders must manage:

- Initial skepticism: Traditional extraction methods have been around for decades, and shifting market perceptions takes time and rigorous demonstration of benefits.

- Regulatory hurdles: New technologies must adhere to increasingly strict environmental and safety standards. This can be intimidating for smaller companies or startups trying to innovate in a crowded market.

- Research and development costs: While the operational gains might be super important in the long run, the battle of funding innovation in a sector already loaded with legacy infrastructure can be challenging.

On the flip side, the opportunities are equally compelling. Early adopters of advanced lithium extraction technologies can benefit from:

- Lower long-term energy and operational costs

- Enhanced product quality with higher lithium purity

- Reduced environmental impact and an improved public image

- Potential government or regulatory incentives for adopting green technologies

Companies that take the initiative to figure a path through these intertwined challenges and opportunities will be better positioned to lead the market in the coming decade.

Integrating Research with Industry: A Collaborative Future

Overcoming the confusing bits of direct lithium extraction technology is not solely the realm of industrial engineers; academic researchers and industry stakeholders must work hand in hand. The exchange of ideas, combined with real-world data from pilot operations, is accelerating progress in this field.

Collaborations among universities, research institutions, and advanced manufacturing players are paving the way. Topics of mutual interest include:

- Improving selectivity in membrane materials

- Testing new electrode configurations for electrochemical cells

- Understanding the little details of how brine chemistry affects overall extraction efficiency

- Optimizing multi-stage extraction systems for better performance

This collaborative research environment is critical for moving beyond laboratory models and into practical, economically viable industrial solutions.

Policy, Regulation, and Environmental Stewardship

Regulatory frameworks will undoubtedly influence how lithium is extracted in the future. Governments worldwide are increasingly focused on not just resource extraction, but doing so in a way that preserves local ecosystems and minimizes carbon footprints.

Policy recommendations that could support advanced extraction methods include:

- Incentives for innovation: Grants and tax advantages for companies that invest in membrane and electrochemical technologies can ease some of the intimidating upfront costs.

- Environmental monitoring requirements: Robust monitoring regimens that keep an eye on water usage and chemical discharge ensure that extraction remains sustainable.

- Collaborative frameworks: Public-private partnerships can accelerate research and implementation of innovative methods, providing a win-win for industry and regulators alike.

Policymakers are tasked with finding a balance between fostering economic growth and protecting natural resources. By working closely with technology developers, they can create an environment where cleaner, more efficient lithium extraction becomes the norm rather than the exception.

Consumer and Market Perception: Steering Through the Social Dimension

Market and consumer perceptions are full of subtle details that can influence the adoption of new technologies. As consumers become increasingly aware of the environmental impact of battery production, the ability of companies to offer sustainably extracted lithium could become a key competitive advantage.

Some subtle details in shaping consumer perception include:

- Transparency: Clear communication about the methods used for extraction builds trust. Companies that can openly share their efforts to minimize environmental harm are likely to win consumer favor.

- Certifications and standards: Industry-recognized certifications for sustainable extraction processes can help dispel doubts and differentiate responsible companies from the rest.

- Media and public relations: Proactive engagement with environmental groups, along with consistent messaging around innovation and sustainability, helps steer public opinion in a positive direction.

Ultimately, the move toward advanced extraction processes is not just a technical evolution—it also marks a shift in how the entire supply chain, from raw material procurement to final product delivery, adapts to the growing demands for quality and sustainability.

Conclusion: A New Era for Lithium Extraction

The development of membrane and electrochemical separation techniques for direct lithium extraction represents a significant turning point in resource recovery. While there are plenty of tricky parts, from complex brine chemistry and material stability to scaling up and economic hurdles, the potential benefits are enticing. Not only do these methods promise a more sustainable and energy-efficient means of recovering lithium, but they could also pave the way for a cleaner battery supply chain—an essential component in the global drive toward greener energy solutions.

By taking a closer look at these technologies and understanding the fine points of every step—from ion selectivity and operating conditions to policy frameworks and market perceptions—industry leaders and investors can work through the challenging bits to create a successful, scalable process. The journey is loaded with twists and turns, but the rewards of a greener, more efficient lithium extraction process are too key to ignore.

As the industry continues to evolve, collaboration between academia, industry, and government will be super important in building the infrastructure needed to meet future demands. The road ahead might be intimidating and filled with tangled issues, but with a focused effort and a commitment to innovation, the future definitely looks bright for direct lithium extraction technologies.

In the grand scheme, the integration of these advanced methods will not only influence the cost and efficiency of lithium extraction but will also serve as a blueprint for other resource recovery sectors. By embracing these emerging technologies, we can usher in an era where sustainable, reliable, and cleaner energy resources become the standard worldwide—benefiting the environment, the economy, and society at large.

Originally Post From https://www.nature.com/articles/s44286-025-00250-6

Read more about this topic at

What Is Direct Lithium Extraction?

Direct Lithium Extraction