Green Chemistry: Paving the Way for a Cleaner Paper Industry

Climate awareness and the need for resource conservation have pushed almost every sector toward a greener future. The paper production industry, historically known for its heavy water consumption and high energy demands, is now in the midst of a serious transformation. Thanks to the innovative approach of green chemistry, manufacturers are now adopting smarter methods and substituting toxic chemicals with more environmentally friendly alternatives. In this opinion editorial, we take a closer look at how these advances are reshaping an industry that has long struggled with some very tricky parts and overwhelming energy needs.

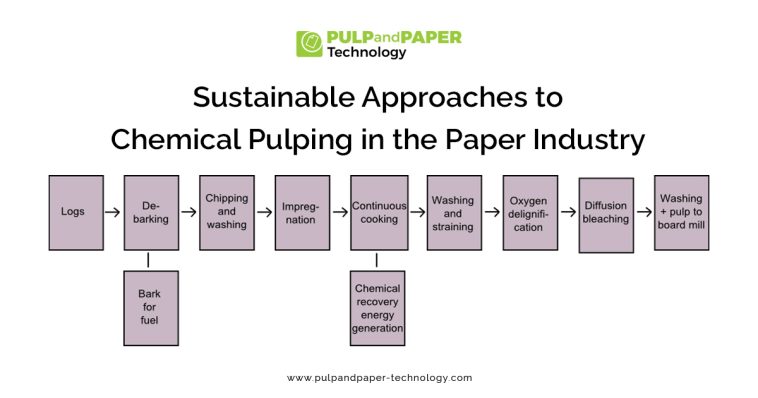

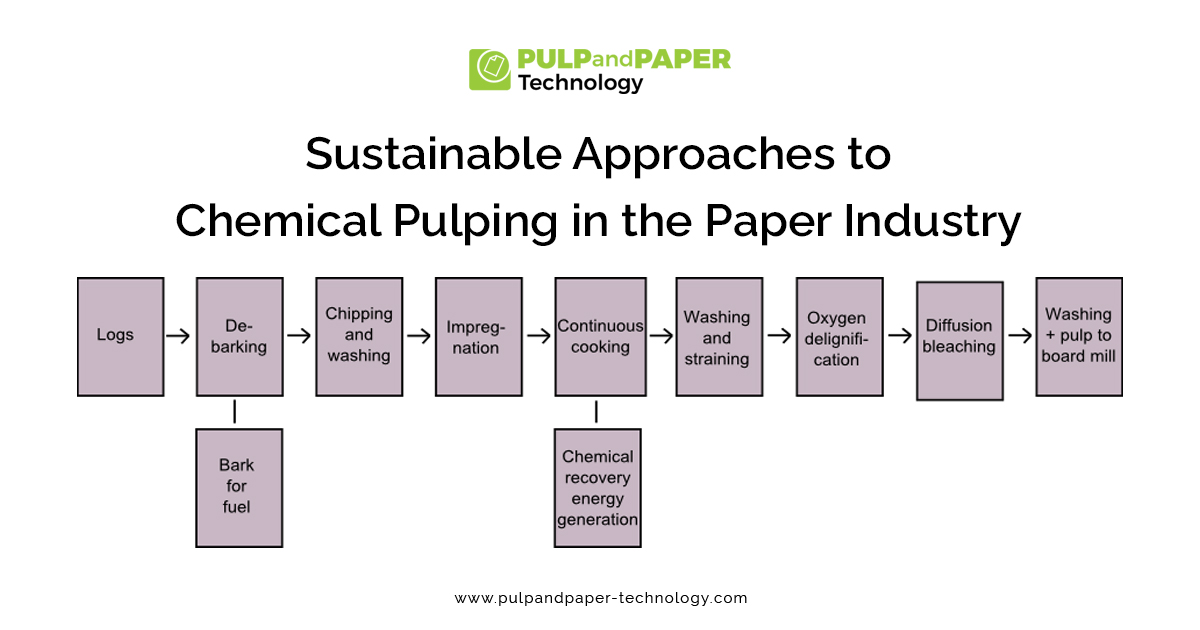

Advanced Pulping Processes: Cutting Through the Confusing Bits

The traditional kraft pulping process has long been the backbone of papermaking. However, it comes with its share of complicated pieces—from high water usage to energy-intensive operations. A key shift has been the move toward biopulping, where natural enzymes and fungi are used to break down lignin (the wood-binding element) instead of relying on harsh chemicals. This alternative not only reduces the need for dangerous substances but also cuts down energy consumption by up to 30%. Such improvements are making it far less intimidating for both businesses and communities to embrace sustainable methods.

Even more innovative is the use of organosolv pulping. This method replaces sulfur-containing chemicals with organic solvents, leading to purer by-products that can be recycled or even repurposed as biofuel. High-consistency pulping systems further reduce water and energy waste by maintaining a denser operation, which means fewer resources used per ton of paper. These alternative techniques are a testament to the industry’s ability to find a path through tangled issues and high energy demands.

Key Advantages of Modern Pulping Techniques

- Reduced Chemical Use: Less reliance on harsh chemicals means fewer adverse environmental effects.

- Improved Energy Efficiency: Methods like biopulping and organosolv pulping significantly cut down energy inputs.

- Resource Savings: A marked reduction in water consumption helps relieve pressure on local water sources.

- By-product Reuse: Purer by-products open new avenues for recycling and reuse, such as creating biofuel.

Eco-Friendly Bleaching Options: Dismantling the Overwhelming Chemical Puzzle

One of the trickiest bits in conventional paper production has always been the bleaching stage. Traditional bleaching, reliant on chlorine-based compounds and chlorine dioxide, generates harmful by-products such as dioxins. These substances have a notorious reputation for polluting water and causing long-term environmental damage. Recognizing these challenges, green chemistry introduces safer alternatives for bleaching.

The adoption of Totally Chlorine-Free (TCF) methods, which use oxygen, ozone, or hydrogen peroxide, marks a profound turning point. Similarly, Elementary Chlorine-Free (ECF) processes—although not completely void of chlorine dioxide—manage to cut down the potential for toxins by reducing emissions significantly. By taking a closer look at these techniques, it becomes evident that modern bleaching options offer businesses a feasible way to reduce their toxic footprint while maintaining product quality.

A comparative table outlining traditional bleaching versus eco-friendly bleaching options can be insightful:

| Aspect | Traditional Bleaching | Eco-Friendly Bleaching |

|---|---|---|

| Chemical Used | Chlorine, Chlorine Dioxide | Oxygen, Ozone, Hydrogen Peroxide |

| Environmental Impact | Pollution and Toxic By-products | Significantly Reduced Toxic Emissions |

| Product Quality | High quality but with environmental cost | Comparable quality with lower environmental impact |

| Scalability | Widely used and proven | Gaining momentum globally |

Revolutionizing Water Use: The Smart Closed-Loop System Approach

Water is an essential element in papermaking, yet its traditional use has been nothing short of wasteful. In conventional plants, huge volumes of water are consumed—not only in pulping and bleaching but also in fiber suspension and drying processes. One transformative innovation in green chemistry is the implementation of closed-loop water systems. These systems are capable of recycling and reusing the same water within the facility, greatly reducing the need to draw fresh water from local sources.

Modern facilities now integrate advanced techniques such as membrane filtration and reverse osmosis to treat water quickly and efficiently. Real-time monitoring of water quality ensures that recycled water meets strict standards, thereby not affecting the final product. Ultimately, such systems can cut freshwater usage by as much as 90%, offering a super important advantage in areas where water scarcity is an increasingly critical issue.

Benefits of closed-loop water systems include:

- Massive Water Savings: Up to 90% reduction in freshwater consumption.

- Environmental Protection: Reduced discharge of contaminated wastewater into local ecosystems.

- Cost Efficiency: Lower operational costs over the long term through reduced resource usage.

- Community Impact: Less strain on regional water supplies helps local communities thrive.

Energy-Efficient Drying Processes: Cutting Through the Energy Demand Labyrinth

The drying stage in paper production is perhaps one of the most nerve-racking segments when it comes to energy consumption. Traditional drying operations can account for up to 70% of a mill’s overall energy use—a statistic that has historically put enormous pressure on production costs and environmental sustainability. However, green chemistry is steadily changing this scenario by bringing forward smarter, energy-efficient alternatives.

Infrared drying technology, for instance, is capable of evenly removing moisture throughout the paper, significantly reducing the energy required. Concurrently, systems designed for steam and condensate recovery efficiently recycle heat energy back into the process. The implementation of heat pumps and waste heat recovery units further demonstrates how the industry is finding its way around the high energy demands.

These innovations not only lower energy usage but also reduce operating costs, making the adoption of green technologies a key business decision for companies wishing to strike a balance between economic output and environmental responsibility.

A summary list of energy-saving techniques includes:

- Infrared drying for rapid and uniform moisture removal.

- Steam and condensate recovery systems to recycle heat energy.

- Heat pumps that recover and repurpose residual heat.

- Advanced process control technology to fine-tune drying duration and temperature.

Integrating Sustainable Additives: A Shift Toward a Cleaner End Product

Green chemistry isn’t only concerned with the pulping and bleaching processes—it also extends to the additives used in paper coating and finishing. Traditionally, many additives were synthetic, potentially toxic, and not biodegradable, making the eventual recycling or safe disposal of paper products a tangled issue. The industry is now embracing a variety of biodegradable and non-toxic additives that support eco-friendly production practices.

For example, starch-based binders, natural latex substitutes, and calcium carbonate fillers produced through environmentally friendly mining practices are being increasingly adopted. The use of these natural and sustainable components is proving to be a game-changer, as it minimizes the environmental impact of waste, particularly when the products reach their end of life. In effect, these shifts in additive technology lead to paper that is safer to handle and simpler to recycle or biodegrade—thus reducing landfill burdens.

Key benefits of sustainable additives include:

- Enhanced Product Safety: Reduced exposure to harmful chemicals.

- Simpler Recycling: Products that break down more naturally and cleanly.

- Lower Environmental Impact: A decreased overall carbon footprint.

- Improved Market Appeal: Consumers increasingly prefer environmentally friendly products.

Economic Ripple Effects: Business Benefits of a Greener Approach

While the environmental benefits of green chemistry are clear, the economic impact is also a significant point of discussion for small businesses and larger manufacturing corporations alike. As the paper industry moves to cleaner, smarter processes, companies are beginning to see a reduction in utility costs, less regulatory pressure, and potential economic incentives from government bodies aiming to stimulate green practices.

The move toward sustainable production is also fostering innovation within the industry, leading to job creation in fields such as process engineering, environmental management, and quality control. Furthermore, consumers are increasingly swayed by environmentally responsible brands, meaning that companies that invest in green technologies can win market share by appealing to a growing base of eco-conscious customers.

This economic shift is not without its tricky parts, however. Transitioning to greener technologies can require upfront investments that may be intimidating for smaller firms. Nonetheless, the long-term savings in operational costs, the improved public image, and the reduced environmental risks form a compelling case for transitioning.

Overcoming the Hurdles: Working Through Tangled Issues in the Transition to Green Chemistry

The journey toward integrating green chemistry into a traditional sector like paper production is not without its challenges. Many companies, particularly those with longstanding operations, face several overwhelming obstacles. These include the high cost of retrofitting older plants, overcoming the resistance to change that naturally exists in any traditional industry, and meeting both regulatory and market demands simultaneously.

A few of these tricky parts include:

- Initial Capital Outlay: Upgrading existing infrastructure to accommodate new technologies can be nerve-racking and expensive.

- Skill Set Adaptation: There is a need for workforce retraining to manage and maintain these new systems effectively.

- Regulatory Hurdles: Even as eco-friendly alternatives are developed, companies must navigate a maze of regulations that can sometimes seem loaded with issues.

- Market Acceptance: Ensuring that consumer trust is maintained during the transition is a delicate process requiring thoughtful communication and robust marketing strategies.

To address these challenges, industry leaders are relying on government incentives, collaboration with research institutions, and a steady focus on long-term benefits over short-term hurdles. In many cases, the combined advantages of reduced energy costs, lower waste production, and enhanced brand reputation far outweigh the initial intimidating expenses.

The Role of Policy and Consumer Demand in Driving Change

Government regulations and consumer preferences are both driving the adoption of green chemistry in the paper industry. Policy initiatives designed to reduce environmental pollution and promote resource conservation are encouraging companies to invest in cleaner technologies. This regulatory push, combined with a market that is increasingly favoring sustainable products, creates a super important catalyst for change.

Government incentives, such as tax breaks and grants for sustainable initiatives, are making it easier for businesses to figure a path toward greener production methods. Simultaneously, consumer education programs that highlight the environmental benefits of recycled and sustainably produced paper are contributing to a shift in market dynamics. As a result, companies that adopt green practices are not only doing right by the planet—they are also positioning themselves to tap into a new, expanding customer base that values sustainability as a core business tenet.

Key areas where policy and market demand intersect include:

- Regulatory Support: Government incentives that lower the cost of transitioning to eco-friendly systems.

- Consumer Trust: Transparent environmental claims help build strong brand loyalty.

- Innovation Grants: Support from both public and private sectors encourages ongoing research into sustainable technologies.

- Long-term Savings: Upfront costs may be daunting, but reduced operational costs and improved market share make green investments highly attractive.

Taking a Closer Look at the Circular Economy Model

The broader focus on a circular economy has brought renewed attention to the idea of minimizing waste and maximizing resource use. In the paper industry, this means designing production processes in such a way that the output not only meets market demands but can also be fully recycled or biodegraded. A move away from linear production methods toward circular approaches is redefining what sustainability looks like.

This model emphasizes three key steps:

- Minimizing Waste: Using cleaner chemical processes and recycling water throughout the manufacturing cycle.

- Resource Maximization: Employing energy-efficient drying techniques and sustainable additives to reduce overall consumption.

- End-of-Life Management: Designing products for recyclability so that they can return safely to the production loop.

The environmental benefits in this context are complemented by significant economic advantages, as companies that practice circular economy principles often enjoy lower production costs and better market stability. This holistic approach to production is a clear example of how environmental and business interests can align when companies are willing to work through the many little twists and complicated pieces that come with holistic change.

Future Outlook: Optimism Amidst the Twists and Turns

Looking ahead, the paper industry’s embrace of green chemistry represents a promising shift toward sustainable production. Continued innovation, strong policy support, and growing consumer demand for environmentally friendly products are setting the stage for an era where traditional manufacturing is transformed by sustainable technologies. As we see more companies dipping into green technology and sharing their success stories, this trend is likely to gain further momentum.

Future developments might include even more advanced methods of pulping that further reduce energy use, breakthrough recycling technologies that allow for even higher rates of water reuse, and new, eco-friendly additive compounds that further lessen the environmental impact of paper products. In addition, the digitization of production processes and smarter process control systems are expected to help companies fine-tune operations down to the nitty-gritty level.

This positive future outlook, however, is not without its challenges. The industrial transition still involves overcoming some tricky parts and the need for significant upfront investments. But by focusing on the long-term benefits—both environmentally and economically—the paper industry can look forward to a more sustainable future that sets a benchmark for industrial manufacturing worldwide.

Conclusion: Embracing a Sustainable Future One Step at a Time

The evolution of paper production through green chemistry is a clear signal that even the most traditional industries can adapt to modern, sustainable demands. Through advanced pulping techniques, eco-friendly bleaching options, closed-loop water systems, and energy-saving drying processes, the industry is finding its way through a maze of complicated pieces and overwhelming energy requirements. Not only do these innovations benefit the environment, but they also offer substantial economic advantages in a market that increasingly values sustainability.

By working together—governments, manufacturers, and consumers alike—an eco-friendly paper ecosystem is within reach. Small businesses and large corporations must continue to support research, invest in new technology, and educate the public. The shifts we see today represent the first steps in a long journey toward a circular economy where waste is minimized, and resources are captured and reused effectively.

Even though the transition is loaded with challenges, the success stories emerging from various companies prove that change is possible when determination meets innovation. As the paper industry continues to embrace these greener practices, it sets an inspiring example for other sectors facing similar twisted regulatory issues and resource constraints. Ultimately, the future of papermaking is not only about producing a familiar product—it’s about creating a legacy of sustainable industry practice that will benefit generations to come.

Originally Post From https://www.apnnews.com/green-chemistry-in-paper-production-innovations-that-reduce-water-and-energy-consumption/

Read more about this topic at

Evolution of green chemistry and its multidimensional …

History of Green Chemistry