Understanding the Global Oxygen Market Landscape

The oxygen market today is a vibrant and multifaceted arena that spans industries and sectors—from high-tech manufacturing to critical healthcare services. As we take a closer look at this evolving market, it becomes clear that both industrial and medical demands are shaping a future where on-site generation, advanced monitoring systems, and regional developments play super important roles in driving growth.

While discussing the significant growth projections, the oxygen industry continues to demonstrate a clear upward trend. With the market valued at around USD 84 billion in 2024 and expected to climb to nearly USD 126 billion by 2033, the steady compound annual growth rate (CAGR) of approximately 4.60% from 2025 to 2033 highlights how vital the role of oxygen is in numerous fields. Analysts attribute this growth largely to increasing demand across industrial applications, expanded use in healthcare, improvements in metal processing, and the rising requirements across chemical production and water treatment.

Industrial Oxygen Use in Global Manufacturing

The industrial oxygen segment stands as a pillar in the global market—not only because of the sheer volume used but also because of its integration into essential processes. Industries like steel manufacturing, chemical production, and even semiconductor processing rely on high-purity oxygen for efficient operation.

Key Insights on Industrial Oxygen:

- Oxygen is essential in the oxy-fuel cutting and welding processes that power metal fabrication industries.

- Steel production, particularly through basic oxygen furnaces, requires massive cubic meters of gaseous oxygen to maintain quality and efficiency.

- Emerging industrial markets in Asia and Africa are increasingly integrating oxygen into their production lines to reduce harmful emissions.

This expansion is fueled by rapid industrial growth in China, India, and Southeast Asia, where the steel and chemical sectors especially are eager to adopt more efficient combustion processes. The benefits of using high-purity oxygen are clear: reduced production times, improved product quality, and a lower carbon footprint when integrated with the right technology.

Medical Oxygen Demand: A Critical Need in Healthcare

When discussing oxygen, the conversation would be incomplete without acknowledging the massive demand coming from the healthcare sector. Medical oxygen is not just a commodity; it is a lifeline for millions of patients around the world.

The increasing prevalence of chronic respiratory diseases such as COPD has pushed the demand for oxygen in hospitals and home-care settings to new heights. With an aging global population and higher rates of respiratory ailments, the need for medical-grade oxygen has become super important.

Factors Driving Medical Oxygen Demand:

- Chronic respiratory conditions require continuous oxygen therapy, especially for patients with long-term needs.

- The growing number of hospital admissions—especially among the elderly—fuels the need for reliable and readily accessible oxygen supplies.

- Recent public health emergencies have shown that the healthcare sector must be prepared for sudden surges in oxygen demand.

This sector is boomed by government initiatives, particularly in nations where pollution or lifestyle factors have contributed to respiratory health issues. The drive to install on-site oxygen generation plants in public hospitals further reinforces the underpinning of medical oxygen as a key piece in the healthcare infrastructure puzzle.

Industrial Versus Medical Demand: The Hidden Details

Despite the impressive figures on paper, the balance between industrial and medical oxygen demand is rife with subtle parts and tricky bits that require careful understanding. On one hand, industrial applications consume a significant volume, while on the other, medical oxygen markets touch the lives of millions in a very direct way.

One of the key differences between these sectors lies in usage patterns and storage technologies. Industrial users may lean towards both gaseous and liquid forms for on-site generation and bulk processing, while hospitals largely favor high-purity and reliable systems for emergency and continuous care.

Key points of this detailed comparison include:

- Form Utilization: Gaseous oxygen accounts for more than half of the consumption, particularly in medium-scale applications such as metal processing and healthcare equipment.

- Technological Integration: Emerging facilities in both sectors are increasingly turning to AI-enabled control systems and on-site pressure swing adsorption (PSA) units to make their oxygen supply more efficient.

- Economic Factors: The cost of infrastructure and logistics remains a significant barrier—especially in remote settings where establishing cryogenic storage or continuous supply networks can be overwhelming due to high initial investments.

Thus, while both segments hold immense opportunities, each grapples with its own twists and turns that shape market strategies and future investment decisions.

Regional Market Analysis: Trends Across the World

When we take a global view of the oxygen market, regional differences provide some of the most telling insights about where the industry is headed. The Asia-Pacific region, for instance, stands out due to its rapid industrialization and expanding healthcare infrastructure.

Asia-Pacific: Driving Industrial and Healthcare Expansion

Asia-Pacific has consistently held the largest market share. Factors such as rapid urban growth, expansive industrial parks, and significant investments in healthcare have created an environment ripe for oxygen market expansion. Countries like China and India are at the forefront:

- China’s massive steel and electronics industries continue to push for high levels of industrial oxygen, particularly in steel plants where on-site gas generation is rapidly gaining favor.

- India has recently taken steps to upgrade its healthcare infrastructure by installing on-site oxygen generation facilities in district hospitals—a move that could transform oxygen availability in rural areas.

- Southeast Asian nations are rapidly expanding their industrial sectors, further increasing demand through the modernization of manufacturing technologies.

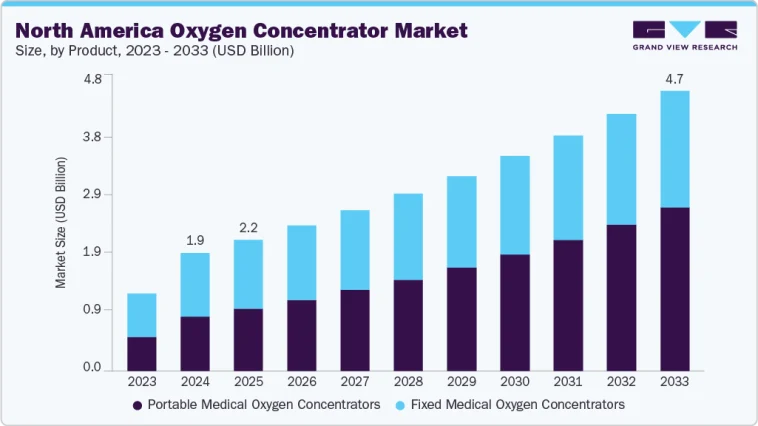

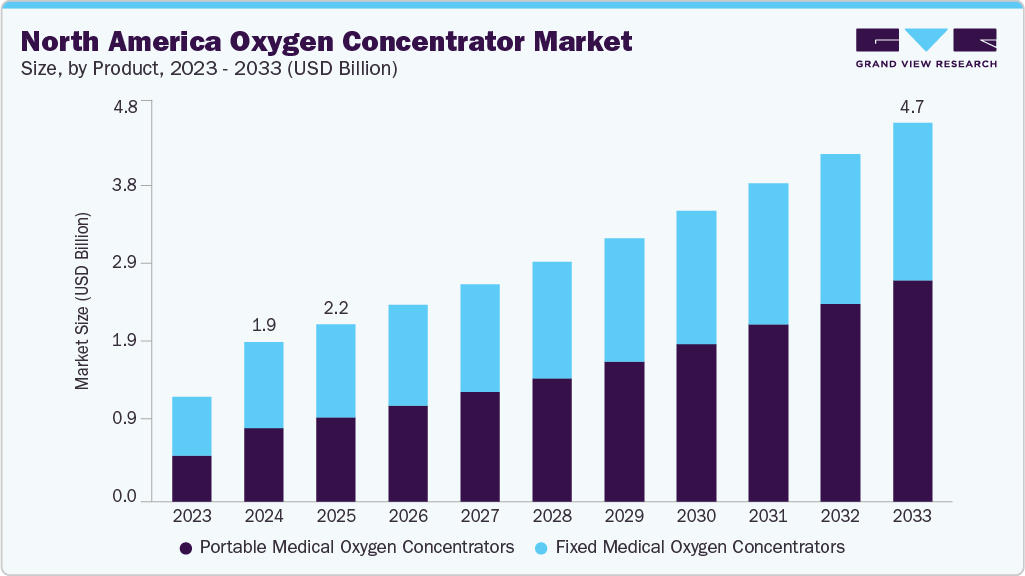

North America: Innovation and Safety in Oxygen Distribution

North America remains a formidable player, thanks to its advanced healthcare systems and strict industrial safety protocols. The U.S. in particular has leveraged its robust research and development landscape to innovate oxygen delivery, including the integration of AI-driven monitoring systems in hospitals.

Highlights of North American oxygen use include:

- Strong adherence to safety standards in both medical and industrial applications.

- Investment in digitalization and IoT-based service integration to optimize oxygen flow and monitor usage in real time.

- Large-scale industrial consumers, such as petrochemical facilities along the Gulf Coast, driving continuous demand for industrial oxygen.

Europe: Balancing Tradition and Technological Advancements

Europe is characterized by a mix of well-established industrial processes and a rapidly modernizing healthcare sector. Alongside traditional metal refining and chemical production, European companies are pushing for greener oxygen production as part of broader decarbonization initiatives.

Some factors shaping the European market are:

- The integration of oxygen in decarbonization strategies, exemplified by its use in carbon capture and hydrogen production.

- A strong regulatory framework that ensures both the safety and quality of oxygen delivered across sectors.

- Ongoing investments in renewable-powered air separation units as companies strive to reduce the environmental impact of traditional oxygen production techniques.

Latin America, Middle East, and Africa: Opportunities Amid Challenges

Emerging markets in Latin America, the Middle East, and Africa present a unique set of opportunities and tricky points. Rapid urbanization paired with industrial diversification is set to push demand; however, logistical issues and infrastructure deficits in remote locations often pose nerve-racking challenges.

Key considerations for these regions include:

- Investments in healthcare, particularly in public hospitals in nations like Egypt and South Africa, are gradually overcoming traditional supply chain obstacles.

- Industrial expansion, such as petrochemical investments in the GCC and large-scale steel production in Brazil, drives the need for continuous oxygen supply.

- Government initiatives and public-private partnerships increasingly focus on building resilient supply networks to mitigate risks related to on-spot supply shortages.

Opportunities and Challenges in Oxygen Supply Chains

Building an effective oxygen supply chain involves managing tangled issues that stretch across production, transportation, and storage. While the market offers substantial opportunities, supply chain vulnerabilities have come to the forefront, particularly during public health emergencies.

Managing Supply Networks Under Public Health Emergencies

The COVID-19 pandemic taught global industries many tough lessons about the importance of reliable oxygen supply chains. Many countries experienced sudden spikes in demand that their centralized production models could not adequately meet, a clear example of how supply networks can become overwhelmed during trying times.

Some of the major supply challenges include:

- Transport and Distribution Issues: The transportation of liquid oxygen requires specialized cryogenic tankers and vacuum-insulated containers. These assets are limited and often stretched thin during emergencies.

- Infrastructure Gaps: Remote healthcare facilities in lower-income regions struggle with consistent power supplies and the technical know-how required to run advanced oxygen production equipment.

- Emergency Preparedness: Many regions lack the necessary buffer storage and alternative supply routes that could ease the strain during sudden demand surges.

Because of these nerve-racking supply chain challenges, both private and public sectors are increasingly investing in decentralized production techniques. Emerging models emphasize on-site oxygen generation, which can help spread the production risk and ensure supply continuity even when central networks are compromised.

Environmental Considerations and Energy Consumption

The production of oxygen—especially via traditional cryogenic air separation—remains energy-intensive and thus has a notable environmental footprint. This issue raises concerns not only for regulatory bodies but also for businesses looking to minimize energy use and carbon emissions.

Environmental and Sustainability Challenges:

- High Energy Demand: Cryogenic distillation is known for its substantial power consumption, which can contribute significantly to greenhouse gas emissions if the energy comes from fossil fuels.

- Carbon Footprint: In regions where coal power remains prevalent, such as parts of China, the environmental impact is even more pronounced.

- Regulatory Pressures: New carbon regulations and mechanisms, such as the EU’s Carbon Border Adjustment Mechanism, are pushing companies to rethink production strategies.

In response, innovators are exploring alternatives like pressure swing adsorption (PSA) systems and integrating renewable energy sources to power traditional air separation units. Behind these efforts lies an industry eager to find its way through the tricky parts of environmental responsibility while ensuring continued growth and innovation.

Innovations and Future Trends in Oxygen Production

As oxygen remains indispensable across countless critical applications, innovation continues to lead the charge towards more efficient, safer, and environmentally responsible production methods. Forward-thinking companies are betting on advancements that could change the game for both industrial and medical markets.

Smart Oxygen Management and AI-Driven Systems

One of the most intriguing developments in oxygen management is the integration of AI-powered systems into the oxygen supply chain. Hospitals and industrial facilities alike are beginning to utilize digital health solutions that include real-time monitoring, predictive analytics, and automated dosing adjustments.

Key benefits of these smart systems include:

- Real-Time Data: Through IoT-enabled sensors, facilities can continuously track oxygen consumption, ensuring that supply meets demand without wasteful overproduction.

- Predictive Maintenance: AI-driven systems can forecast when equipment might need servicing, reducing downtime and preventing supply disruptions.

- Optimized Consumption: By adjusting oxygen flow rates based on patient vitals or industrial requirements, these systems help minimize wastage and improve overall efficiency.

By embracing these digital tools, institutions not only enhance their operational efficiency but also contribute to more sustainable resource management. This approach offers a promising way forward for both healthcare and industrial sectors, especially in times when every drop of oxygen counts.

On-Site Generation Systems: A Game-Changer for Decentralized Supply

The shift toward on-site oxygen generation is another transformative trend. By installing systems like pressure swing adsorption (PSA) directly in hospitals, steel plants, and other facilities, organizations can reduce dependence on long-distance oxygen transport and centralized production networks.

This decentralized model offers several notable advantages:

- Cost Efficiency: On-site systems often have lower long-term operating costs compared to continuously delivered liquid oxygen, making them a smart choice for facilities with steady oxygen demand.

- Enhanced Reliability: With generation occurring at the point of use, the likelihood of supply chain disruptions is reduced—a critical benefit during public health emergencies or industrial busy periods.

- Flexibility: These systems can be tailored to the specific needs of a facility, whether that is a small regional hospital or a large industrial complex.

Although there are certain initial challenges, such as the nerve-racking costs and twisted issues connected to installation and maintenance, the long-term benefits make on-site generation a compelling option. As technology continues to improve and installation costs decrease, it is expected that more sectors will opt for this model, further decentralizing oxygen production and enhancing overall supply security.

Emerging Market Opportunities and Strategic Partnerships

Looking ahead, the oxygen market offers numerous opportunities for growth and collaboration. Major players in the industry—such as Linde plc, Air Liquide, Air Products and Chemicals, Inc., NIPPON SANSO HOLDINGS CORPORATION, and Messer Group—are not only expanding their production capacities but are also actively investing in new technologies and digital innovations.

Key Strategic Moves in the Market:

- On-Site Generation Investments: These market leaders are prioritizing on-site gas generation to cut down on logistic complications. By forging long-term contracts with both industrial and healthcare clients, they ensure a steady ecosystem of supply and demand.

- Digital Monitoring Integration: Companies are increasingly deploying IoT-enabled monitoring systems that help them track oxygen consumption and perform predictive maintenance. This step not only boosts efficiency but also reduces the chances of unwanted supply shortfalls.

- Decarbonization Initiatives: With tighter environmental regulations and a growing need for cleaner industrial practices, oxygen producers are exploring renewable-powered production methods and carbon capture technologies to reduce the carbon footprint of their operations.

These initiatives reflect a market that is eager to take a closer look at every element of its value chain—from production and distribution to the final applications in both hospitals and industrial settings. The result is a more resilient network that is better able to withstand supply chain shocks and meet evolving consumer and regulatory demands.

Final Thoughts: The Future of the Oxygen Market

As we cast our eyes to the future, the oxygen market stands at a crossroads where industrial might and healthcare necessity converge. It is a field full of promising opportunities yet also riddled with issues that demand smart, innovative responses. Whether it is through the adoption of AI-driven smart monitoring systems, the growing appeal of on-site oxygen generation, or the steadfast efforts to decarbonize production processes, the market is steadily incorporating solutions that aim to solve its tricky parts and twisted issues.

Investors, policy-makers, and industry leaders alike must figure a path that not only meets today’s demand but is also robust enough to address the nerve-racking challenges posed by sudden demand spikes and infrastructural limitations in remote areas. Regulatory frameworks need to be adapted to support rapid technological deployments while ensuring safety and environmental sustainability—a balance that is critical as the oxygen market continues to evolve.

In summary, the oxygen market isn’t just confined to the deep recesses of industrial plants or hospital corridors—its influence spans far wider. With the global aging population, the rise in respiratory conditions, and the ever-expanding industrial sectors, oxygen is proving to be one of those quiet yet super important resources that sustains both life and modern manufacturing.

The market is now on a journey to take full advantage of decentralized production models, smart analytics, and sustainable practices. It is exactly this convergence of necessity, innovation, and efficiency that will help stakeholders not only overcome the nerve-racking parts and confusing bits but also seize emerging opportunities as they come along.

As the world continues to advance and adapt, the oxygen market is poised to remain a key component in global operations. By harnessing technological advances and forming strategic partnerships, stakeholders can manage their way through the subtle parts and small distinctions that define this dynamic market, ensuring that the supply of oxygen—and thus, the lifeblood of countless industries—remains uninterrupted and robust.

In closing, it is clear that the future of the oxygen market is filled with promise, provided that industry players can work through the tangled issues and tricky parts that remain. With sustained investments, smart policy interventions, and continuous technological innovation, oxygen will continue to be a driving force in both industrial and healthcare sectors worldwide.

Whether you are a key decision-maker in a large manufacturing facility or a healthcare provider in need of reliable oxygen supply, understanding the minute details of this market is crucial. The next decade will undoubtedly bring further changes, and those who are prepared to steer through the twists and turns will undoubtedly harness the full potential of this essential commodity.

By taking a proactive stance and adopting resilient strategies, the oxygen market can continue on its promising trajectory—a trajectory that not only meets the demands of a growing global population but also supports the sustainable and technological progress crucial in today’s competitive environment.

| Sector | Main Drivers | Key Challenges |

|---|---|---|

| Industrial | High demand in steel production, chemical processing, and metal fabrication | Logistics, energy consumption, and safety in cryogenic storage |

| Healthcare | Rising chronic respiratory diseases, aging demographic, emergency preparedness | Infrastructure limitations, technology integration, and consistent supply |

It is by addressing both the off-putting challenges and capitalizing on the super important opportunities that the oxygen market will continue to thrive. Following these trends, industry experts are optimistic that the coming years will see improvements not only in production capacity but also in ensuring that oxygen is available where and when it is needed the most.

Ultimately, whether through decentralized production, digital monitoring, or innovative environmental initiatives, the oxygen market’s evolution is a testament to human ingenuity in overcoming tricky parts and managing tangled issues. In a world where every resource counts, oxygen stands out as a clear example of necessity meeting innovation—fueling progress one breath at a time.

This comprehensive transformation is something that everyone—be it industrial magnates, healthcare providers, or policy-makers—should watch closely. The next wave of breakthroughs in oxygen production and management promises to deliver both economic and social value, reinforcing the idea that in our modern world, even the most basic elements can drive monumental change.

As we step further into the future, the oxygen market represents a dynamic space where industrial growth and healthcare advancement intersect. It exemplifies how both sectors can come together, each leveraging its particular strengths to overcome the nerve-racking challenges and take full advantage of every emerging opportunity.

In this evolving landscape, it is essential to keep an eye on innovations, strategic partnerships, and regulatory responses. With continued attention and investment, the oxygen market will not only meet today’s demand but will also be exceptionally well-prepared for tomorrow’s challenges—a sentiment as clear as the air we breathe.

Originally Post From https://www.marketdataforecast.com/market-reports/oxygen-market

Read more about this topic at

Oxygen Therapy Market Size, Share & Trends Report, 2030

Oxygen Market Size, Share & Growth Report, 2033