The Evolving Landscape of 5-Isopropyl-m-Xylene: Opportunities and Challenges in the Chemical and Pharmaceutical Industries

The 5-Isopropyl-m-Xylene market today is witnessing an exciting shift, driven by its increasing role as a chemical intermediate in the manufacture of high-performance materials. As industries from pharmaceuticals to specialty coatings lean on this versatile compound, the market is on a steady upward trend. In this opinion editorial, we dig into the current market dynamics, regional growth patterns, production challenges, and strategic opportunities for businesses aiming to secure a foothold in the evolving world of 5-Isopropyl-m-Xylene.

Our analysis nests a detailed look at market forecasts, the demand for precise chemistry, and the importance of innovation in process automation and industrial synthesis. Throughout this article, we will highlight the key aspects using easy-to-understand language, sprinkle in bullet lists and tables where needed, and replace potentially complex phrases like “complexities” or “intricacies” with friendlier synonyms such as “tangled issues” or “fine points.”

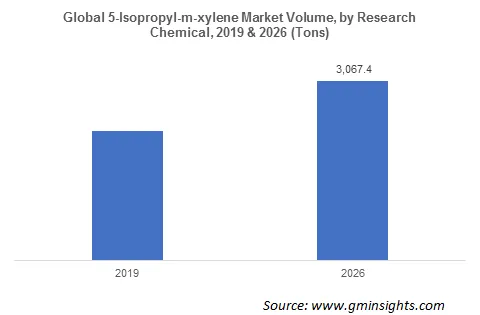

Global Market Outlook and Forecast Trends

The global market for 5-Isopropyl-m-Xylene is anticipated to grow from a value of USD 219.3 million in 2025 to an impressive USD 431.5 million by 2035. With a compound annual growth rate of 7.0% over this forecast period, the market demonstrates robust potential. The growth is largely attributed to its increasing use as an intermediate in multiple sectors, especially for producing terephthalic acid and related derivatives, as well as in pharmaceutical synthesis and specialty polymers.

This upward trajectory is not without its twists and turns. The market’s steady progress is influenced by several factors, including:

- Rising demand for precision synthesis and high-purity aromatics

- Significant investments in industrial research and development

- The compound’s structural versatility and compatibility with advanced chemical processes

These factors underscore the importance of 5-Isopropyl-m-Xylene in modern chemical manufacturing, making it a must-have ingredient for companies looking to produce high-quality derivatives with controlled reactivity.

Projected Growth and Market Dynamics

From 2025 through 2035, market players expect significant milestones. For instance, the market is projected to steadily climb, with values estimated at USD 234.7 million in 2026, reaching USD 307.6 million by 2030. A table summarizing these figures can help clarify the growth pattern:

| Year | Market Value (USD Million) |

|---|---|

| 2025 | 219.3 |

| 2026 | 234.7 |

| 2027 | 251.1 |

| 2028 | 268.7 |

| 2029 | 287.5 |

| 2030 | 307.6 |

| 2035 (Projected) | 431.5 |

This table provides a bird’s-eye view of the predictable market expansion—a trend largely buoyed by industrial and research advancements, as well as the compound’s efficient integration into multiple production streams.

Diverse End-Use Applications Driving Expansion

One key factor powering the surge in this market is the diverse application range for 5-Isopropyl-m-Xylene. It plays a pivotal role as an intermediate in several sectors that benefit from its specific properties, including its solvent capacity, thermal stability, and compatibility with various chemical processes.

Applications Across Industries

The compound finds utility in numerous fields, some of which include:

- Terephthalic Acid and Related Derivatives: This segment holds a 57.3% share in market revenue. When used in polyester production and advanced polymer synthesis, 5-Isopropyl-m-Xylene helps streamline production efficiency.

- Pharmaceutical Synthesis: Accounting for roughly 38.8% of demand, the compound is essential for formulating active pharmaceutical ingredients (APIs) under strict regulatory conditions.

- Solvents and Coatings: With a contribution of around 15-20%, its use in adhesives, inks, and packaging materials supports various industrial applications, particularly in the automotive sector.

- Laboratory and Organic Synthesis: It is commonly employed in advanced synthesis methods such as Suzuki coupling and carboxylation, serving as a critical reagent in fine chemicals research.

Its versatility allows producers and researchers to tap into several high-growth sectors—a significant advantage in boosting the compound’s long-term market potential. The compound’s dependable characteristics in high-yield reactions and purity control are highlighted in technical studies and corporate strategy updates alike.

Regional Highlights: Asia-Pacific, North America, and Europe

The geographical distribution of growth provides another insightful view into the potential of 5-Isopropyl-m-Xylene. Market expansion is largely driven by robust industrial and R&D investments in Asia-Pacific and steady industrial output in North America and Europe.

Asia-Pacific: A Rapidly Expanding Hub

In the Asia-Pacific region, rapid industrial expansion and increased investments in research capabilities are key forces propelling the market. This growth is reflected in higher production volumes for specialty chemicals and a burgeoning demand for advanced materials in areas such as agrochemicals, perfumery, and high-performance coatings.

- Industrial Investment: Governments and private sectors are stepping up to build renewable, efficient production facilities, including high-purity distillation and automated synthesis plants.

- Regional Production Hubs: Countries within the region, notably China and India, are securing their positions as leaders in the production of specialty solvents and intermediates, with growth rates of 9.5% and 8.8% respectively.

- Export-Oriented Strategies: Manufacturers are increasingly developing their capabilities to meet both domestic and international demands, underscoring the global significance of their output.

North America and Europe: Steady Demand and Quality Focus

North America, with a forecast growth rate of 6.0%, takes a slightly more cautious approach characterized by stringent regulatory frameworks and a focus on high-purity production standards. Meanwhile, Europe—particularly countries like Germany, the UK, and France—emphasizes low impurity levels and advanced refining practices. For example:

- Germany: With an 8.1% growth rate, German producers have optimized production processes to meet high standards in chemical formulations used in fine chemicals and adhesives.

- United Kingdom: A steady growth pace of 6.7% is supported by rising activity in research labs and niche chemical producers, where custom blending processes are refined to meet specialty market demands.

- USA: Producing at a 6.0% growth rate, American companies are focused on regulatory compliance and positioning the compound for use in industrial adhesives, lubricants, and coatings in line with strict purity standards.

Regional cooperation in technology development and standardization helps these regions maintain a steady flow of supply for industries that rely heavily on high-grade aromatic intermediates.

The Role of Industrial Innovations in Market Growth

Innovative production methods and process automation play a crucial role in the current market trends. With the focus shifting toward enhanced process optimization, companies are harnessing new technologies to meet the demand for high-purity, cost-effective intermediates.

Technological Advances and Their Impact

Novel approaches in catalytic synthesis and refining have enabled producers to reduce impurities and lower energy consumption in batch processes. These technical improvements support lower per-unit production costs and create a competitive edge in both commodity and specialty chemical segments.

- Process Automation: Digital control and automation help maintain consistent purity levels required by stringent quality standards, particularly in pharmaceutical and coating industries.

- Improved Catalysts: The adoption of advanced catalytic systems improves reaction selectivity, leading to fewer byproducts and enhanced yields in oxidation processes.

- Optimized Production Lines: Automation and digital monitoring systems give manufacturers an ability to figure a path through production challenges, ensuring product consistency and compliance with global standards.

Investments in these process improvements help companies manage the tricky parts of production—like fluctuating feedstock prices and the tangled issues of purification—and allow them to move closer to delivering high-purity products at scale. These improvements not only support enhanced cost efficiency but also help market players better adapt to regulatory changes and evolving consumer demands for cleaner production methods.

Supply Chain, Regulatory, and Production Challenges

Despite the promising growth, the 5-Isopropyl-m-Xylene market faces several challenging areas. The production and supply chain remain impacted by fluctuations in benzene-derived feedstocks, which can cause unpredictable price shifts and supply shortages.

Tangled Issues in Feedstock Volatility and Substitution Pressures

One of the most difficult bits to manage is feedstock volatility. The price of benzene and crude oil can directly affect the cost of producing 5-Isopropyl-m-Xylene. Alongside this, the potential adoption of substitute aromatics by some industries creates competition that may slow down growth in certain segments.

The key supply chain pressures include:

- Upstream Price Fluctuations: Volatile prices for feedstocks lead to unpredictable production costs, which can ripple through the entire value chain.

- Substitution by Alternative Solvents: In cost-constrained or environmentally sensitive applications, companies might opt for alternative solvents or intermediates, affecting overall demand.

- Regulatory Fragmentation: Differing chemical standards, environmental requirements, and safety documentation across regions such as North America, Europe, and Asia-Pacific add extra layers of process management that are both intimidating and nerve-racking for producers.

Managing Supply Chain and Quality Challenges

To better manage these tricky parts, companies are investing in multiple strategies to figure a path through production hurdles:

- Implementing advanced purification techniques to ensure consistent product quality.

- Deploying digital quality control measures to monitor batch purity, especially for pharmaceutical intermediates.

- Engaging in strategic partnerships with feedstock suppliers to secure reliable sources and mitigate price volatility.

This multi-pronged approach not only helps in managing the complicated pieces of regulatory and production challenges but also positions companies to better meet market demands with minimal disruptions.

Competitive Landscape: Key Industry Players and Their Strategies

A competitive field has emerged in the niche segment of 5-Isopropyl-m-Xylene. Major players are fighting for market share by emphasizing quality, process innovation, and responsive global supply chains. Companies such as Tokyo Chemical Industry (TCI), Sigma-Aldrich (now part of Merck KGaA), Spectrum Chemical, Toronto Research Chemicals, Santa Cruz Biotechnology, and J&K Scientific are leading the charge.

Strategies for Gaining a Competitive Edge

These firms are using several methods to stay ahead in the market:

- High-Purity Production: Firm commitments to producing high-grade chemicals ensure that research labs and industrial clients receive consistent quality that meets international regulatory standards.

- Technical Support and Documentation: Extensive technical data and robust quality assurance processes help customers navigate the fine points of using 5-Isopropyl-m-Xylene safely and effectively.

- Global Distribution Networks: By building efficient and transparent logistics systems, these companies are able to serve markets across North America, Europe, and Asia-Pacific efficiently.

- Innovation in Custom Synthesis: Tailored product offerings for niche applications such as advanced polymer manufacturing and active pharmaceutical ingredient (API) preparation drive customer loyalty and resilience against substitutes.

Given the research-driven nature of this market, competition is intense yet healthy. Firms that offer technical support and rapid delivery while embracing product customization stand a greater chance of capturing long-term contracts and sustaining market leadership.

What Lies Ahead: Possibilities and Strategic Recommendations

The outlook for 5-Isopropyl-m-Xylene remains optimistic, with work taking the wheel on several fronts to further boost market growth. For industry participants, strategic foresight and the willingness to adopt innovative production methods are key to taking advantage of this evolving market environment.

Diverse Opportunities in Advanced Material Synthesis

Several promising areas await investors and producers, including:

- Sustainable Production Innovations: With an increasing emphasis on cleaner chemical processes, research into sustainable synthesis methods could reduce production costs and mitigate environmental concerns.

- Expanding Downstream Capacities: As demand grows from specialized market segments—such as pharmaceuticals, high-performance lubricants, and niche coatings—upgrading production facilities to handle precise formulation requirements will be super important.

- Customization and Collaborative R&D: Partnerships between chemical manufacturers and end-users, like polymer and coating producers, can generate tailored solutions that fulfill very specific requirements, thereby enhancing customer satisfaction and driving repeat business.

Industry leaders may also benefit from closer collaboration with regulatory bodies. Over time, streamlining the documentation and approval process across regions will help companies work through the tricky parts of varying compliance demands. Such collaborations may foster a more cohesive regulatory environment, reducing the need to juggle multiple standards across different regions.

Analyzing the Future Challenges and Opportunities

As companies prepare for the next decade, it is crucial that they not only continue to focus on technological breakthroughs but also manage the tangled issues related to supply chain disruptions and regulatory differences. Some strategic recommendations include:

- Investing in Automation: Automation and digital tracking systems can help companies steer through production uncertainties and ensure robust quality control.

- Strengthening Feedstock Partnerships: Long-term contracts with reliable suppliers can provide stability in costs and supply, countering risks associated with feedstock volatility.

- Expanding R&D Collaborations: Close collaboration with research institutions and end-user industries can lead to the development of new applications and innovative derivatives of 5-Isopropyl-m-Xylene.

- Targeted Market Segmentation: By identifying specific regions and applications with high growth potential, companies can optimize their production strategies and market penetration efforts.

Furthermore, companies need to take a closer look at their internal processes to improve efficiency, reduce waste, and enhance safety. Addressing the nerve-racking challenges related to raw material fluctuations and certification overhead will be a key element in maintaining a competitive edge.

Long-Term Implications for Economic and Industrial Sectors

The sustained growth of the 5-Isopropyl-m-Xylene market can have far-reaching implications beyond the chemical industry. As this compound becomes more entrenched in the production of advanced polymers, resins, and pharmaceutical intermediates, it paves the way for related sectors to innovate and expand. For instance:

- Automotive and Packaging Industries: The improved solvent and coating properties derived from 5-Isopropyl-m-Xylene can lead to better-performing materials in manufacturing lightweight vehicles and durable packaging solutions.

- Healthcare and Pharmaceutical Innovation: Its role in producing high-purity intermediates directly supports the development of cleaner, more effective active pharmaceutical ingredients, thereby enhancing drug safety and efficacy.

- Industrial Manufacturing: As high-performance coatings and adhesives gain wider adoption, manufacturers can benefit from products that deliver improved durability and resistance to environmental factors.

These links between the 5-Isopropyl-m-Xylene market and broader industrial sectors mean that investors and business leaders must consider the compound’s potential as part of a holistic strategy for sustainable industrial growth. By aligning production strategies with the needs of end-user markets and regulatory trends, companies can unlock new revenue streams and reinforce their market positions.

Strategic Collaboration for Sustainable Growth

In light of the evolving market, collaboration among stakeholders is more crucial than ever. Key strategies include:

- Integrated Supply Chain Solutions: Coordinated efforts between raw material suppliers, chemical producers, and logistics partners can help companies get around the tangled issues of feedstock volatility.

- Joint-R&D Ventures: Collaborative research efforts with universities and research institutes can foster innovation in sustainable production methods and product customization, easing the nerve-racking process of adapting to changing market demands.

- Regulatory Harmonization Initiatives: By working together with regulatory authorities internationally, companies can simplify the process of meeting regional standards, reducing the multiple layers of certification and documentation that complicate the supply process.

In our interconnected world, everyone from small business operators to major industrial players stands to benefit from a more united approach. A collaborative spirit can help smooth out many of the confusing bits encountered when dealing with international regulations, pricing adjustments, and landscape shifts in chemical production.

Conclusion: Taking the Wheel in a Transforming Market

It is clear that the 5-Isopropyl-m-Xylene market is not only growing but also transforming in significant ways. The compound’s rising use as an intermediate across various industry chains—from chemical and pharmaceutical sectors to niche specialty markets—provides a robust platform for continued expansion over the next decade and beyond.

While the market faces some intimidating challenges, such as feedstock volatility and regional regulatory differences, the overall picture remains promising. Industrial innovations, collaborative efforts, and a firm commitment to quality offer a road map to overcoming these tricky parts. Companies that remain agile, invest in modern production processes, and align their strategies with market needs are best positioned to reap the rewards.

In closing, the outlook for 5-Isopropyl-m-Xylene is bright. Businesses that can figure a path through the tangled issues of production costs, regulatory requirements, and supply chain disruptions—as well as harness the compound’s wide-ranging applications—will find themselves well-placed in a market that is both dynamic and full of possibilities. As the compound becomes increasingly embedded in the manufacture of essential goods, its significance as a market driver will only grow, ensuring that all who buckle down to meet these demands will help shape the future of industrial manufacturing and chemical innovation.

By taking a closer look at both the well-trodden and the unexplored paths of this market, industry stakeholders can unlock new opportunities for growth and sustainability—a future defined by smart innovation, strategic partnerships, and the ability to manage even the most complicated pieces with confidence and clarity.

Originally Post From https://www.futuremarketinsights.com/reports/5-isopropyl-m-xylene-market

Read more about this topic at

Xylene Market Size, Growth, Share & Competitive …

Xylene Market Size, Share, Growth & Trends Report, 2030