Editorial Overview: Sumitomo’s Bold Step into Decentralized Hydrogen Production

The renewable energy world is buzzing with news as Sumitomo Corporation of Americas has teamed up with Independence Hydrogen, a U.S.-based company that has found an innovative way to reclaim hydrogen from otherwise wasted gas streams. This landmark partnership promises to ramp up decentralized hydrogen production, offering a fresh take on turning industrial byproducts into a valuable, clean energy resource. In this opinion editorial, we explore the new collaboration, weigh its implications for industries like transportation and manufacturing, and ponder what it might mean for the future of local clean energy production.

This new venture is especially interesting because it emerges at a time when many companies are trying to figure a path through the many twists and turns of transitioning from fossil fuels to renewable energy. Independence Hydrogen, which currently processes about 1.2 tonnes of hydrogen per day from the excess gases generated by chlor-alkali manufacturing in Pennsylvania, now has plans to boost production to 7 tonnes per day with Sumitomo’s backing. The idea is straightforward yet powerful: capture what would be wasted and convert it into a locally available energy source that could have numerous applications in industrial decarbonization and beyond.

Turning Wasted Gases into a Local Energy Resource

One of the most innovative aspects of this collaboration is the focus on turning waste into wealth. Instead of letting excess gases escape into the atmosphere or get flared, Independence Hydrogen’s approach is to capture and refine these contaminants into usable hydrogen. This on-site recovery system is not only a super important environmental win, but it also makes the energy supply chain more efficient and cost-effective.

The idea resonates strongly with the push for industrial decarbonization, where every little twist counts in using resources more responsibly. By transforming waste into a super important energy commodity, companies can cut greenhouse gas emissions and improve local energy security. Here are some key benefits:

- Reduction in greenhouse gas emissions

- Enhanced local energy independence

- Improved cost-effectiveness in energy production

- Increased operational efficiency in manufacturing sectors

Turning waste into a local resource addresses several tangled issues regarding supply chain efficiency and environmental responsibility. This model could signal a major step forward in rethinking how industries manage their byproducts and shift toward renewable energy sources.

Understanding the Production Process: The Nitty-Gritty of Hydrogen Refining

To truly appreciate the innovation behind this project, it’s essential to get into the fine points of the hydrogen refining process. At its core, the process involves collecting excess gases from chemical manufacturing—where these gases are typically dismissed as a burden—and purifying them into a form that can be safely and effectively used in energy applications.

Some of the key steps include:

- Collection of excess gases from industrial processes

- Purification and separation to isolate hydrogen

- Storage and transportation in decentralized systems

- Distribution to industries such as transportation and power generation

This process is filled with challenging parts that require precision and expertise. Independence Hydrogen’s ability to manage these tricky bits has positioned them as a leader in local hydrogen production. Now, with Sumitomo’s global clout and experience, we can expect to see significant improvements in efficiency and scale.

Scaling Challenges: Managing Your Way Through Tricky Parts and Tangled Issues

The journey to ramp up production from 1.2 tonnes to 7 tonnes per day isn’t without its nervous aspects. Scaling any energy production method involves a host of technical, logistical, and regulatory challenges—all of which are a mixture of intimidating hurdles and complicated pieces. Some of these challenges include:

- Ensuring consistent hydrogen quality for various industrial applications

- Expanding the distribution network across wider geographic regions

- Addressing cost issues that arise from scaling operations

- Meeting the environmental and safety standards required by regulatory bodies

Each of these factors comes with its own set of nerve-racking complications. Yet, by partnering with Sumitomo—a company that has been rigorously investing in scalable hydrogen infrastructure—the project appears well-equipped to address these challenges head-on. It’s an exciting opportunity to watch a local project go big while ensuring that the subtle parts of the production process maintain high quality and compliance.

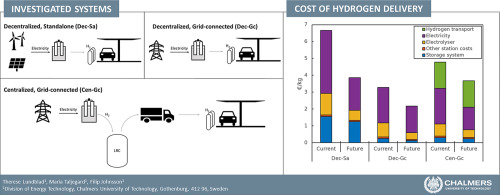

Decentralized versus Centralized Hydrogen Systems: A Comparative Look

The idea of decentralized hydrogen production is gaining momentum, particularly in response to the limitations seen in centralized systems. Let’s compare these two approaches:

| Aspect | Decentralized Production | Centralized Production |

|---|---|---|

| Flexibility | Localized control and rapid responsiveness | Heavily reliant on major distribution hubs |

| Cost Efficiency | Potential lower costs due to reduced transportation and storage needs | High costs linked to long-distance distribution |

| Environmental Impact | Utilizes industrial byproducts, cutting emissions locally | Concentrated production may lead to higher localized emissions |

| Scalability | Can be scaled up incrementally with local support | Requires massive infrastructure investment up front |

This table illustrates that decentralized models, such as the one advanced by Independence Hydrogen, are especially well-suited for addressing the local energy needs of industrial centers. By having production on-site or near the point of consumption, many of the tangled issues with energy transportation and distribution could be greatly reduced.

Economic Upsides: Critical Implications for Industrial and Transportation Sectors

The economic potential behind this project is promising. Not only does decentralized hydrogen production directly contribute to environmental goals, but it might also drive significant savings and efficiency improvements in sectors like manufacturing and transportation. By capturing hydrogen that would otherwise go unutilized, companies can turn an excess byproduct into a valuable asset.

From an economic standpoint, the benefits may include:

- Reduced energy costs due to localized production

- Creation of new job opportunities in emerging clean energy fields

- Increased competitiveness for local industries by lowering operational costs

- Enhanced energy security that reduces dependence on imported fuels

Expanding the production capacity in a decentralized manner helps companies strike a better balance between supply and demand, potentially easing the financial strain caused by inconsistent energy availability. In this sense, the collaboration is not only an environmental win but a critical economic strategy for industries that rely heavily on energy-intensive processes.

Pushing the Boundaries of Industrial Decarbonization

Industrial decarbonization has been a hot topic in recent years due to the pressing need to curtail greenhouse gas emissions. This partnership between Independence Hydrogen and Sumitomo is a key example of how industries are rethinking their approach to energy use. By recovering hydrogen that would otherwise pollute the environment, the collaboration supports a broader strategy of reducing a company’s carbon footprint.

Decarbonization is full of problems and nerve-wracking challenges. However, several key points indicate that initiatives like this one can be game-changing:

- Improved energy efficiency in manufacturing processes

- Reduction in reliance on fossil fuels

- Enhanced opportunities for tech innovations in fuel cell development

- Potential to foster public-private partnerships that accelerate acceptable standards in the industry

By taking a closer look at how hydrogen can be recovered and reused, stakeholders can figure a path through many of the complicated pieces of decarbonizing industrial operations. This move may also inspire more companies to invest in technologies capable of turning waste into an essential energy resource.

Sumitomo’s Role: Planting Deeper Roots in the U.S. Hydrogen Market

Sumitomo’s entry into this arena is not just about capital investment—it’s also about sharing expertise and infrastructure know-how on a global scale. The sum of Sumitomo’s contributions can be seen in its broader strategy of investing in scalable hydrogen infrastructure across multiple regions worldwide. With its strong track record, Sumitomo brings a wealth of experience in handling both the regulatory and technical challenges that come with expanding energy projects.

This collaboration is a two-way street: for Sumitomo, it’s a chance to plant deeper roots in the U.S. hydrogen market; for Independence Hydrogen, it means enhanced resources and the opportunity to push further into the field of decentralized energy production. The partnership is a clear signal that major players are willing to work hand-in-hand with smaller, innovative companies to develop solutions that address some of the most confusing bits in the modern energy landscape.

When we consider the broader market, the involvement of a global industrial heavyweight like Sumitomo might also encourage further consolidation and collaboration within the hydrogen energy sector. Such collaborations could reduce market uncertainty and boost investor confidence, further accelerating the adoption of sustainable energy practices in multiple industries.

The Hidden Complexities of Distribution and Local Market Growth

Even as production scales up, one of the critical challenges that remain involves the local distribution infrastructure. Making sure that the generated hydrogen actually reaches the industries that need it is a tricky part of the process. Decentralized production has an edge here: proximity to end-use locations often means fewer concerns about transportation losses or storage issues.

However, there are hidden complexities to consider, such as:

- Coordinating logistics between production sites and end users

- Balancing supply across different geographic areas

- Ensuring that safety and environmental regulations are met at every stage

- Overcoming potential resistance from communities not yet familiar with hydrogen technology

Working through these subtle details is nerve-racking at times, yet they are essential for ensuring that the benefits of decentralized production are fully realized. As local governments and private companies increasingly recognize the value of renewable energy sources, we may see accelerated efforts to build out robust distribution channels, promotional policies, and community engagement initiatives.

Fuel Cell Technology: Digging Into the Fine Points of Clean Power Solutions

Another critical piece of the puzzle is fuel cell technology, which converts hydrogen into electricity with high efficiency and minimal environmental impact. Fuel cells have emerged as one of the leading technologies in the shift toward clean energy, and they are particularly intriguing for the transportation sector, where their efficiency and low emissions set them apart from traditional combustion engines.

The integration of fuel cell technology into decentralized hydrogen production platforms can foster several benefits:

- Reliable clean energy generation for industrial applications

- Significant reductions in harmful emissions compared to fossil fuel power sources

- A more resilient energy grid due to distributed generation capacity

- Opportunities for further technological improvements and cost reductions

By combining the on-site production capabilities of companies like Independence Hydrogen with the state-of-the-art fuel cell systems supported by larger industrial players, the clean energy market could see a seamless integration of renewable production and consumption. This is a pivotal moment for industries that are trying to sort out the many tricky parts of transitioning to sustainable energy: every step forward in fuel cell technology is a small twist in the drive toward a cleaner future.

Regulatory and Safety Considerations: Getting Around the Nerve-Racking Hurdles

Any shift in industrial energy production is bound to attract regulatory attention. With hydrogen being a highly reactive gas, safety protocols and environmental standards must be met to protect both human lives and the surrounding environment. This is one domain that is often loaded with issues, requiring companies to work with multiple regulatory agencies to ensure that all safety and environmental guidelines are strictly followed.

Some of the key hurdles include:

- Complying with local, state, and federal safety standards

- Ensuring that production facilities continuously meet environmental compliance

- Training staff to manage and operate hydrogen systems safely

- Adapting to shifting regulatory landscapes as technologies evolve

Even though these hurdles may seem overwhelming at first glance, the strategic partnership with Sumitomo injects a measure of confidence that these complications can be carefully managed. By pooling resources and sharing expertise, both companies can jointly steer through the delicate balance between innovation and safety, ensuring that the hydrogen recovered and produced meets all required standards.

Future Implications: How Decentralized Hydrogen Production Could Change the Landscape

Looking ahead, the decentralized production of hydrogen could be a pivotal game changer for several reasons. By localizing production and reducing transportation distances, industries can significantly cut down on cost and inefficiency. Moreover, this model offers a resilient alternative to centralized energy networks—especially in times when disruptions in large-scale energy grids can have widespread impacts on local economies.

Some probable future implications include:

- Enhanced energy security and independence for industrial hubs

- Improvement in public health outcomes due to reduced local emissions

- The emergence of local microgrids that integrate various renewable energy sources

- Opportunities for technology transfer and replication in other sectors and regions

Decentralized systems are particularly interesting in the context of community-driven energy initiatives. In many cases, local facilities that incorporate renewable energy are better at addressing their own supply issues. With companies like Independence Hydrogen setting an example, we might soon see similar models adopted in other industrial regions, paving the way for a more sustainable energy future on a broader scale.

Global Trends and the Growing Momentum of Clean Hydrogen

Globally, nations and major corporations are increasingly focused on reducing carbon emissions and adopting cleaner energy sources. Within this global context, hydrogen has emerged as one of the key components of future energy strategies. Fueling industries from transportation to power generation, hydrogen represents a versatile alternative in the modern energy mix.

There are several factors driving this global interest:

- Government policies pushing for renewable energy adoption

- Growing consumer demand for environmentally friendly products and practices

- Advancements in technology that make hydrogen production more cost-effective

- Collaborative efforts between governments and private enterprises to build new infrastructure

This trend is far from a passing phase. As more breakthroughs occur and companies start to manage their way through the tricky parts of transitioning to renewable energy, we can expect hydrogen to occupy an increasingly central role in global energy policy. The partnership between Sumitomo and Independence Hydrogen is a clear sign that traditional industrial giants are ready to engage with newer, greener technologies.

Lessons from the Past and Hints of a Greener Future

History has shown that every major technological leap is filled with twists and turns. From the industrial revolution to the rise of the internet, breakthroughs have been accompanied by periods of intense change and adjustment. Similarly, the push towards decentralized hydrogen production is one step in a long journey toward building a cleaner, more sustainable world.

Reflecting on previous industrial transformations, several lessons emerge:

- Adopting new technologies often requires a rethinking of traditional practices

- Strategic partnerships can help manage the nerve-racking challenges involved

- Localized production methods can lead to greater resiliency and cost savings

- The transition to a cleaner future is a gradual process that builds upon small, critical improvements

By taking a closer look at these fine details, industry experts and stakeholders can better appreciate the significance of the Sumitomo-Independence Hydrogen deal. It is an opportunity to learn from past challenges and apply those insights to a strategy that could redefine how we produce and distribute clean energy.

Concluding Thoughts: Steering Through the Future of Clean Energy

The strategic partnership between Sumitomo Corporation of Americas and Independence Hydrogen offers an optimistic glimpse into the future of decentralized hydrogen production. By turning what was once considered industrial waste into a super important energy commodity, this venture not only paves the way for cleaner industrial processes but also redefines the relationship between environmental responsibility and economic feasibility.

Clearly, the path ahead is loaded with challenges—from the confusing bits of scaling production to the overwhelming tasks of ensuring safety and regulatory compliance. Still, these nerve-racking issues are being addressed by industry leaders who have the vision to work together and take a closer look at innovative approaches. With Sumitomo’s global reach and Independence Hydrogen’s on-the-ground expertise, we are watching a blueprint being laid out for the future of decentralized clean energy.

As industries continue to seek smarter, greener ways to operate, partnerships like these could very well become the cornerstone of a new energy era. By localizing production, reducing transportation needs, and optimizing supply chains, decentralized hydrogen production might soon become the de facto standard for companies looking to reduce emissions and drive efficiency. In this rapidly evolving energy landscape, it’s essential to find your way through the many tricky parts and tangled issues with a mindset that focuses on innovation, collaboration, and progress.

Ultimately, the expanded role of decentralized hydrogen production is more than just a technological evolution—it is a necessary shift towards a sustainable future that benefits not only industrial players but also local communities and the planet as a whole. As more companies adopt such methods, and as regulatory frameworks adjust to support these changes, we anticipate a leap forward that will set the stage for a cleaner, greener, and more economically resilient world.

In conclusion, while the journey toward widespread clean hydrogen utilization is filled with fine points and subtle challenges, the collaborative model represented by Sumitomo and Independence Hydrogen is a promising solution to some of the most confusing bits of our current energy supply model. It is an inspiring example of how innovation, when paired with strategic partnerships, can turn waste into wealth and help secure a bright, sustainable future for industries worldwide.

Originally Post From https://www.hydrogenfuelnews.com/sumitomo-backs-decentralized-hydrogen-push-in-us-with-independence-hydrogen-investment/8571759/

Read more about this topic at

Decentralised Hydrogen Production – an overview

Decentralised hydrogen production: A faster path to …