Fluoropolymer Coatings: A Market at the Crossroads of Innovation and Challenge

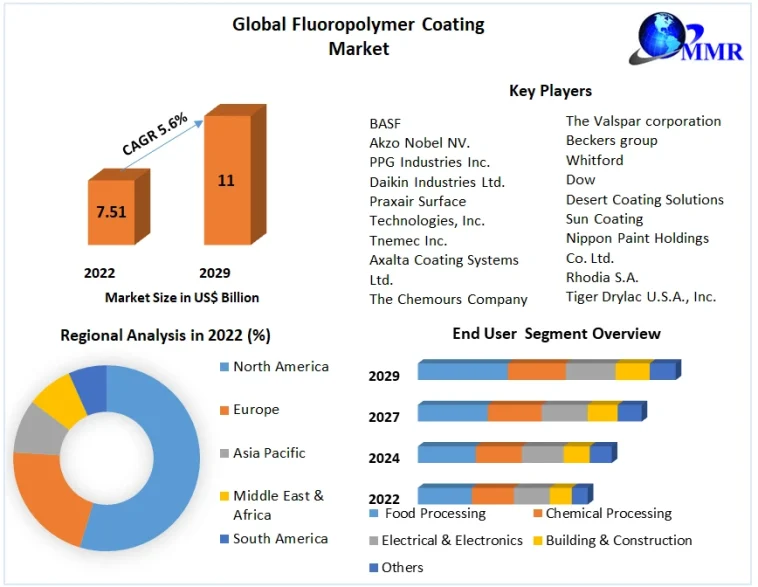

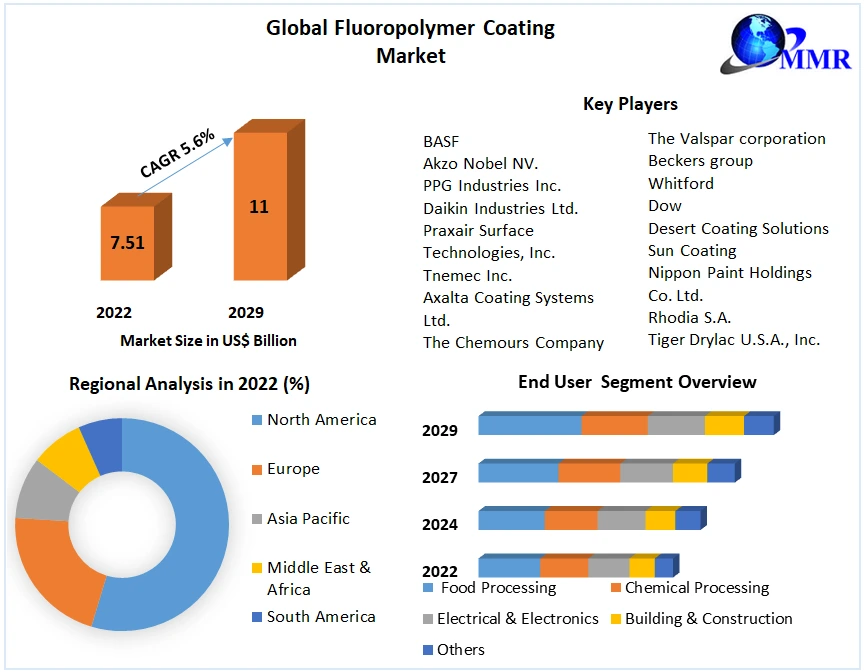

In recent years, the fluoropolymer coating market has steadily emerged as a key player in the global coatings arena. With strong projections indicating growth from USD 5.1 billion in 2025 to USD 10.3 billion by 2035, this market is ripe for discussion. Today, we explore the tangled issues, emerging opportunities, and the tricky parts faced by industry stakeholders as they try to figure a path through a rapidly evolving landscape.

Evaluating the Global Outlook for Fluoropolymer Coatings

The forecasted compound annual growth rate (CAGR) of 7.3% over the next decade signals healthy expansion, driven largely by an increased demand for corrosion-resistant and durable coatings. In sectors such as automotive, chemical processing, and electronics manufacturing, the need for such high-performance coatings stands out as a must-have solution. The global market not only addresses conventional applications but also penetrates emerging fields that require materials with exceptional chemical resistance and thermal stability.

Critical Analysis of Market Drivers and Growth Segments

Key factors fueling this growth include:

- Enhanced durability and longevity in harsh operating environments

- Rising industrialization across Asia-Pacific, notably in China and India

- Innovations in performance coatings with improved resistance properties

- Growing demand in specialized industries such as automotive and electronics

The impressive performance of PTFE coatings, which currently hold a 40.2% share in the market, is a testament to the technology’s practical benefits. This product’s inherent resistance to chemicals and high temperatures positions it as a go-to choice for various industrial applications. Meanwhile, the dominance of the chemical processing sector—projected to capture a 35.4% share—underscores the critical role of fluoropolymer coatings in ensuring operational safety and prolonging equipment life.

Table: Key Metrics and Market Projections

| Metric | 2025 Estimate | 2035 Projection |

|---|---|---|

| Market Value (USD Billion) | 5.1 | 10.3 |

| CAGR (2025-2035) | 7.3% | |

| PTFE Coatings Industry Share (2025) | 40.2% | |

| Chemical Processing Segment Share (2025) | 35.4% | |

Industrial Applications and Sector-Specific Trends

Fluoropolymer coatings offer a range of applications that are essential across different industries. Their unique properties, such as low friction and durability, are particularly attractive in automotive and electronic manufacturing, where tough operating conditions demand reliable materials. The market does face some intimidating challenges, such as high production costs and price volatility associated with key raw materials like PTFE. However, the benefits—prolonged product life and enhanced safety—more than compensate for these nerve-racking issues.

Expanding Use in the Automotive and Chemical Sectors

In the automotive industry, manufacturers are increasingly investing in fluoropolymer coatings to boost the performance and safety of vehicle components. Coatings that can withstand extreme temperatures and chemical exposure are critical for parts used in engine assemblies, battery casings, and other vital systems. Similarly, in chemical processing plants, these coatings protect infrastructure against corrosive substances, thereby reducing maintenance downtime and extending the operational life of expensive equipment.

Dive into the Benefits for Electronics and Aerospace Applications

Electronics manufacturers have also begun to rely heavily on fluoropolymer coatings. These materials provide optimal electrical insulation and protect delicate components from thermal stress. Aerospace applications are no less demanding. The requirement for materials that can manage severe heat, withstand volatile chemicals, and offer low drag in high-speed environments has led to widespread adoption of optimized coating solutions by leading industry players.

Regional Perspectives: Asia-Pacific, Europe, and Beyond

The geographic spread of market growth reveals interesting trends. While the United States and the United Kingdom show steady appreciation in market value, the Asia-Pacific region, particularly China and India, is witnessing explosive growth, driven by rapid industrialization and favorable government incentives.

Identifying the Growth Potential in India and China

India’s growing market, with a projected CAGR of 9.2%, is especially noteworthy. Increased capital expenditures in automotive, chemical, and electronics corridors are propelling demand for high-performance coatings. Local toll-coaters are enhancing their capabilities, making it easier for both global and domestic players to find their way through regulatory hurdles and tariff barriers.

South Korea and the United States: Steady Growth Amid Global Shifts

South Korea’s anticipated growth of 6.7% demonstrates the country’s strong industrial base and advanced technological infrastructure. In the United States, a steady CAGR of 6.2% through 2035 is bolstered by significant R&D investments focused on next-generation PTFE, FEP, and PFA formulations. These regions have built robust supply chains, making it easier to manage the tricky parts and unpredictable fluctuations inherent in production costs.

Table: Regional CAGR Projections (2025-2035)

| Country | CAGR (%) |

|---|---|

| United States | 6.2% |

| United Kingdom | 5.8% |

| China | 8.0% |

| India | 9.2% |

| South Korea | 6.7% |

Technological Advancements and R&D Innovations

The drive for innovation in production processes is a major focus area for industry leaders. Companies such as Akzo Nobel, PPG Industries, and The Sherwin-Williams Company are heavily investing in R&D to improve the performance and longevity of fluoropolymer coatings. Innovations in nano-coatings, improved dispersion techniques, and the development of eco-friendly alternatives are at the forefront of these efforts.

Exploring Next-Generation Coating Formulations

Significant advances have been made as companies actively work through the confusing bits of ensuring material safety and efficiency. The integration of nanotechnology in coating formulas has resulted in products that not only resist extreme environmental conditions but also facilitate easier application methods. These innovations are playing a critical role in overcoming the expensive and nerve-racking production costs associated with raw materials.

Pioneering Eco-Friendly and PFOA/PFOS-Free Alternatives

The environmental impact of traditional fluoropolymer coatings has been a concern for many stakeholders. Manufacturers are now under pressure to produce coatings that comply with strict environmental regulations regarding PFOA and PFOS. The shift toward eco-friendly formulations is not only essential for regulatory compliance but also beneficial in opening up new markets, particularly those focused on sustainable industrial practices. This move is indicative of a broader trend in the industry where technological advancements combine with environmental responsibility to create products that cater to the needs of modern manufacturing.

Investment Trends and Economic Implications in the Coatings Sector

Investors and market strategists have paid close attention to the fluoropolymer coating market, given its significant potential for high returns. With growth projected nearly to double within a decade, stakeholders are actively debating whether the current pricing and production challenges outweigh the long-term rewards. Many experts agree that while raw material price volatility and production challenges present formidable hurdles, the opportunities for innovation and market penetration offer promising prospects for sustained economic returns.

Navigating the Ups and Downs of Production Costs

One of the most challenging aspects for producers is managing the unpredictable costs associated with raw materials. In a market where every improvement in durability or performance can translate to significant operational savings, understanding and managing these production expenses is super important. Manufacturers and distributors have responded by exploring cost-effective alternatives and optimizing production processes to reduce dependency on pricey inputs.

Balancing Regulatory Compliance with Market Demand

Regulatory standards, particularly those concerning the use of PFOA and PFOS, are full of problems that require companies to continuously adapt their formulations and processes. The need to balance customization with compliance means that businesses must be constantly alert to shifts in government policies. This dynamic regulatory environment might seem overwhelming at times, but it also pushes companies to innovate and sustain competitive advantages through the development of advanced coating technologies.

Insights on the Competitive Landscape and Key Industry Players

The competitive environment in this market is a mix of dominant players with extensive portfolios and emerging companies that focus on innovation and cost-effective solutions. Leaders like Akzo Nobel, PPG Industries, and The Sherwin-Williams Company have established themselves as the titans of their field, providing a wide range of products across multiple sectors. These companies are heavily involved in R&D, customizing coatings to meet the diverse and specific needs of various applications, from automotive to aerospace.

Breaking Down Market Leadership and Investments

Major companies have maintained their leadership through:

- Robust product portfolios covering a wide range of coating types

- Significant investments in R&D to update traditional formulations

- Global distribution networks that allow them to reach multiple regions

- Tailored solutions that meet sector-specific requirements

Emerging firms in the sector, such as Arkema and Solvay, are also gaining attention with their focus on innovative, cost-effective coatings. These companies are not only exploring new materials but also adopting advanced production techniques to create products that are resilient and eco-friendly, thereby offering consumers the very latest in coating technology.

Table: Leading Companies in the Fluoropolymer Coating Market

| Company | Key Strengths |

|---|---|

| Akzo Nobel N.V. | Extensive product portfolio and global reach |

| PPG Industries, Inc. | Innovative R&D and tailored formulation expertise |

| The Sherwin-Williams Company | Diverse coatings applications across multiple sectors |

| Axalta Coating Systems, LLC | Focus on performance and industry-specific needs |

| The Chemours Company | Advanced formulations for enhanced durability |

Evaluating the Challenges: Production Costs and Price Volatility

Yet, the route to success in this sector is not without its bumpy stretches. Managing the unpredictable pricing of raw materials—especially PTFE—constitutes one of the most intimidating obstacles for industry players. The fluctuating costs not only affect production expenses but can also have a ripple effect on the final pricing of the end products. For stakeholders trying to figure a path through these challenges, the task can sometimes feel overwhelming.

Strategies to Overcome Price Instability

Industry participants are taking several measures to mitigate these issues:

- Adopting Alternative Materials: Companies are exploring cost-effective substitutes that can lower reliance on expensive raw ingredients.

- Innovative Production Techniques: Improvements in production processes are helping to reduce waste and energy consumption, thereby contributing to cost savings.

- Diversification: Expanding product lines across different segments can help balance the impact of price volatility on any single product or region.

- Strategic Partnerships: Collaborations between manufacturers, distributors, and research institutions are fostering a shared approach to tackling price instability and enhancing product performance.

These strategies indicate that while the production side presents complicated pieces and nerve-racking challenges, there is a clear pathway forward for those willing to invest in research and innovative manufacturing approaches.

Environmental Regulations and the Shift to Safer Coatings

One of the more subtle details in the current market scenario is the growing scrutiny around environmental compliance, especially concerning PFOA and PFOS chemicals. With governments around the world imposing stricter guidelines, the pressure is on companies to shift toward safer, eco-friendly solutions. This trend not only demonstrates a commitment to environmental responsibility but also opens new avenues for innovation in product formulation.

How Regulatory Changes Spur Technological Innovation

Manufacturers are now rethinking their approach to formulation and production. By investing in green technologies and alternative chemistries, companies can produce fluoropolymer coatings that meet both performance and sustainability benchmarks. This evolution is critical for long-term market viability as consumers and regulatory bodies alike become more focused on environmental impact. The emphasis on creating safer coatings is a win-win situation: it addresses environmental concerns while boosting the market with newer, improved products.

Example of Regulatory Influence in Practice

Mitsuhiro Suwabe, President of Tokyo Silicone Co., Ltd., highlighted the importance of diversification in product offerings and the company’s commitment to safer coating solutions. By moving away from materials that rely on regulated chemicals, coating manufacturers are not only complying with regional mandates but also setting a standard for innovation in material science. This approach is gaining traction, particularly among companies that must steer through stringent guidelines while maintaining product performance.

Market Impact on Industrial Equipment and Construction Sectors

Beyond the automotive and chemical sectors, fluoropolymer coatings are increasingly essential in the industrial equipment and construction markets. Their ability to shield equipment from corrosive chemicals and high temperatures makes them indispensable in harsh environments. This necessity has led to a modest but steady market share in these areas, reflecting the versatility and broad applicability of fluoropolymer products.

Application in Industrial Equipment

Industrial machinery and equipment, constantly exposed to extreme conditions during operations, benefit immensely from fluoropolymer coatings. These coatings serve as a protective layer that prevents wear and tear, thereby reducing downtime and maintenance costs. For companies with heavy operational demands, this translates into improved safety, fewer interruptions, and better overall performance.

Role in Modern Construction and Infrastructure Projects

In the construction sector, these coatings are used for applications ranging from protective linings in buildings to specialized coatings for architectural exteriors. The benefits include enhanced durability and an extended lifespan for materials exposed to unpredictable weather and corrosive substances. As countries across the globe continue to invest in modern infrastructure, the role of high-quality fluoropolymer coatings remains a key element in ensuring sustainability and quality construction.

Looking Ahead: Emerging Trends and Future Considerations

As we peer into the future of fluoropolymer coatings, several emerging trends and considerations come to the fore. The market is expected to evolve, not just in terms of size and revenue, but also through the incorporation of new technologies and more sustainable practices. Stakeholders must be ready to take a closer look at shifting market dynamics and adjust their strategies accordingly.

Dive into the Role of Digital Transformation and Automation

Digital transformation is increasingly influencing every aspect of industrial manufacturing, and the coatings sector is no exception. Automation in production lines and real-time monitoring of coating applications are becoming standard practices. These advances help companies manage quality control, reduce waste, and optimize manufacturing cycles. By integrating smart technologies, businesses can tame the nerve-racking unpredictability of raw material costs and ensure consistently high performance in their products.

Exploring New Market Niches and Custom Applications

There is growing interest in exploring customized solutions that cater to niche needs. Sectors such as semiconductor manufacturing, high-precision electronics, and medical devices are all looking for specialized coatings that can deliver performance under unique conditions. As customization becomes more critical, companies are investing in technologies that allow for a finer distinction between product variants. This commitment not only broadens the market reach but also strengthens customer relationships as each client receives a product specifically designed to meet their exact requirements.

Final Thoughts on the Fluoropolymer Coating Market

In conclusion, the fluoropolymer coating market stands at an exciting crossroads. It is a sector ready to grow robustly over the next decade, powered by high-performance products, technological advancements, and widespread industrial demand. While there are several obstacles—ranging from production cost unpredictability to any nerve-racking regulatory changes—the market’s adoption of innovative practices and eco-friendly solutions is helping to overcome these hurdles.

Key Points for Industry Stakeholders

- Market Growth: A projected CAGR of 7.3% reveals ample opportunities for investors and manufacturers alike.

- Technological Innovations: Continuous investment in R&D is essential for maintaining competitive performance and reducing production issues.

- Regulatory Environment: Transitioning to eco-friendly and PFOA/PFOS-free alternatives is not just a regulatory necessity but also a market differentiator.

- Regional Dynamics: While traditional markets in the US and Europe offer steady growth, rapid industrialization in Asia-Pacific can drive exceptional returns.

- Competitive Landscape: Dominant players combined with emerging innovators ensure a dynamic and evolving market.

As industry players work through the twisted challenges of production and regulatory demands, the relentless focus on innovation ensures that the market is well-positioned to meet future needs. By integrating smarter manufacturing techniques, adopting environmentally sustainable practices, and customizing solutions for niche applications, the fluoropolymer coating industry is paving the way for a brighter, more resilient future.

Overall, the balance of challenges and opportunities in this market makes it an exciting space to watch. Stakeholders who can navigate the tangled issues of production costs and regulatory compliance, while also embracing advanced technology, stand to gain significantly in this highly competitive arena. The coming years will likely bear witness to transformative changes whereby traditional coatings are enhanced by new materials and digital innovations, ensuring that the market not only survives but thrives in the face of global industrial advancements.

A Look at the Road Ahead

As we move forward, it will be super important for companies to continue collaborating, sharing insights, and investing in innovative solutions that address both cost and performance challenges. The intricate processes of research, development, and market adaptation will play an indispensable role in defining who leads this market. With robust global demand on the horizon, the need to manage production expenses and adhere to stringent environmental standards becomes not merely a challenge, but a driving force for continuous improvement and excellence.

In the final analysis, fluoro-based coating technologies represent one of those compelling intersections of necessity and innovation. The road ahead is filled with both promising opportunities and nerve-racking challenges, but for those who can figure a path through the twists and turns, the rewards promise to be substantial and long-lasting. The ongoing dialogue among manufacturers, regulators, and end users will remain vibrant as all parties work together to shape a safer, more resilient industrial future.

Ultimately, the fluoropolymer coatings arena exemplifies how a well-established technology can evolve to meet modern challenges through smart innovation and strategic foresight. The narrative of growth, technological progression, and regulatory adaptation is one that deserves close attention from all stakeholders. Whether you are an investor considering entry into the market, an engineer focused on product performance, or a business leader driving operational excellence, the time to take a closer look at the latest advancements in fluoropolymer coatings is now.

With the market’s projected steady rise in value and an unyielding push for quality and sustainability, the future of fluoropolymer coatings seems both promising and transformative. As we continue to witness industrial evolution in real time, the sector’s ability to solve its tricky parts through technology and strategy will, in the end, define its success. In this exciting period of change, each development is another step toward a future where high-performance, eco-friendly coatings become the standard in protecting critical infrastructure across industries worldwide.

Originally Post From https://www.futuremarketinsights.com/reports/fluoropolymer-coating-market

Read more about this topic at

Fluoropolymer Coating Market

Fluoropolymer Coatings Market Size Report, 2024-2030